Description

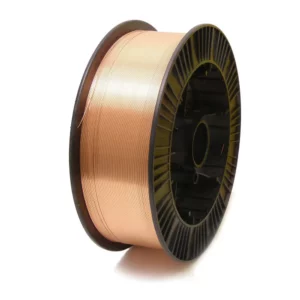

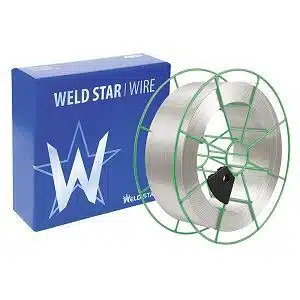

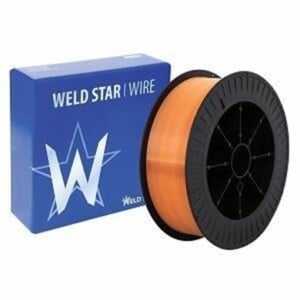

Sifmig 985 MIG Copper Brazing Wire – 0.8 mm x 12.5 Kg

The Sifmig 985 MIG Copper Brazing Wire, with a diameter of 0.8 mm and a weight of 12.5 Kg, is a top-tier wire that boasts a composition of at least 98.5% copper, complemented with deoxidizing elements. This wire is meticulously crafted for MIG welding of copper, ensuring a robust and durable bond. Its unique formulation not only guarantees optimal welding outcomes but also provides resistance to both high temperatures and corrosion. Specifically designed for joint welding of high-oxygen copper joints and materials, it is recommended for material thicknesses greater than 6mm to pre-heat the component to temperatures between 600ºC and control cooling post-welding to ensure a slow and gradual reduction in heat.

Key Features:

- High Copper Content: Contains a minimum of 98.5% copper, ensuring superior welding quality.

- Deoxidizing Elements: Infused with elements that counteract oxidation, promoting cleaner and more resilient welds.

- Temperature and Corrosion Resilience: Offers resistance against high temperatures and corrosion, ensuring the longevity of the weld.

- Specialized Welding: Specifically designed for joint welding of high-oxygen copper joints and materials.

Typical Applications:

The Sifmig 985 MIG Copper Brazing Wire is tailored for:

- Copper Welding: Perfect for MIG welding tasks involving copper, ensuring a strong and lasting bond.

- High-Oxygen Copper Joints: Ideal for joint welding of high-oxygen copper joints and materials.

- Thick Materials: Recommended for materials with a thickness greater than 6mm, with specific pre-heating and post-welding cooling guidelines.

Welding Positions

For use in all positions.

Specifications

| Product Type | Mig Wire – Brazing |

| Part Number | WO980812 |

| Weight | 12.5 KG |

| Diameter | 0.8mm |

| Melting Point (DegC) | 1025 |

| Ultimate Tensile Strength (U.T.S.) N/mm2 | 220 |

| Shielding Gas | Argon |

| Current Type | Direct Current (DC+) |

Typical Weld Metal Weld Composition

| Sn (Tin) | 0.85% |

| Mn (Manganese) | 0.25% |

| P (Phosphorus) | 0.01% |

| Si (Silicon) | 0.2% |

| Cu (Copper) | Bal |

Typical Mechanical Properties

| Melting Point | 1025˚C |

| Ultimate Tensile Strength | 220 N/mm² |

| Hardness | 70 |

Material to be Welded

Used in MIG welding of copper, this wire is ideal for joint welding of high-oxygen copper joints and materials. If material thickness is >6mm, pre-heat component 600ºC< – control cooling after welding to ensure slow, gradual reduction in heat.

BS: 2901 C7. EN ISO 24373: Cu 1898 [CuSn1]

Reviews

There are no reviews yet