Description

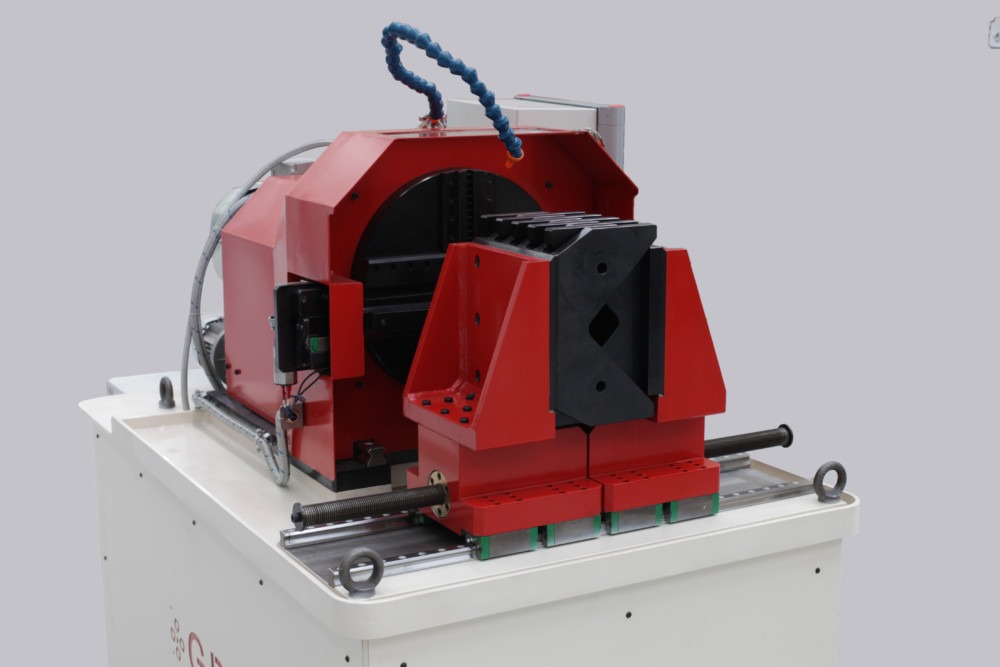

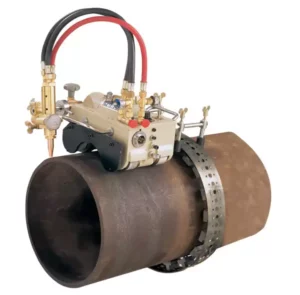

Stationary Pipe Bevelling Machine (SB320)

RANGE O/D 33 – 320 MM (1 1/2″ – 12 3/4″)

Stationary pipe beveller for pipes from 1 1/2″ to 12 3/4″ diameter.

Features

- Onboard control panel for managing all the functions of the machine, the working phases and the full automatic cycle

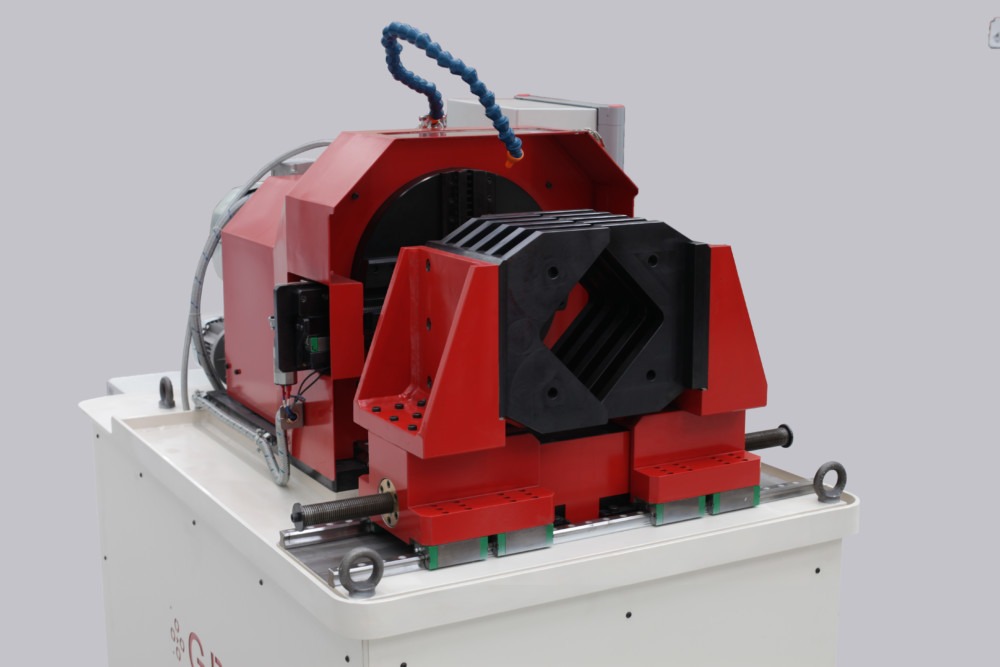

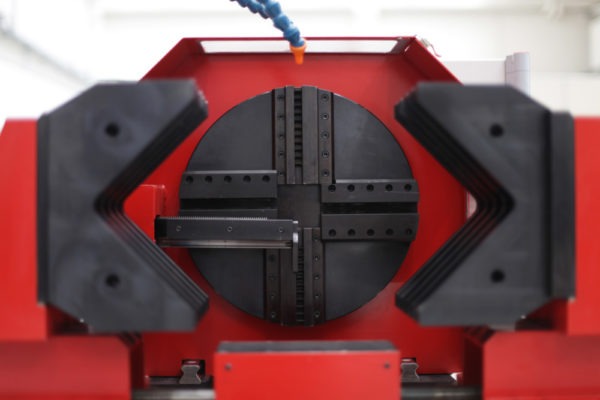

- Self-centring and deformation-free prismatic jaws with automatic tightening torque sensor

- Automatic pipe positioning

- Onboard automatic lubricating system

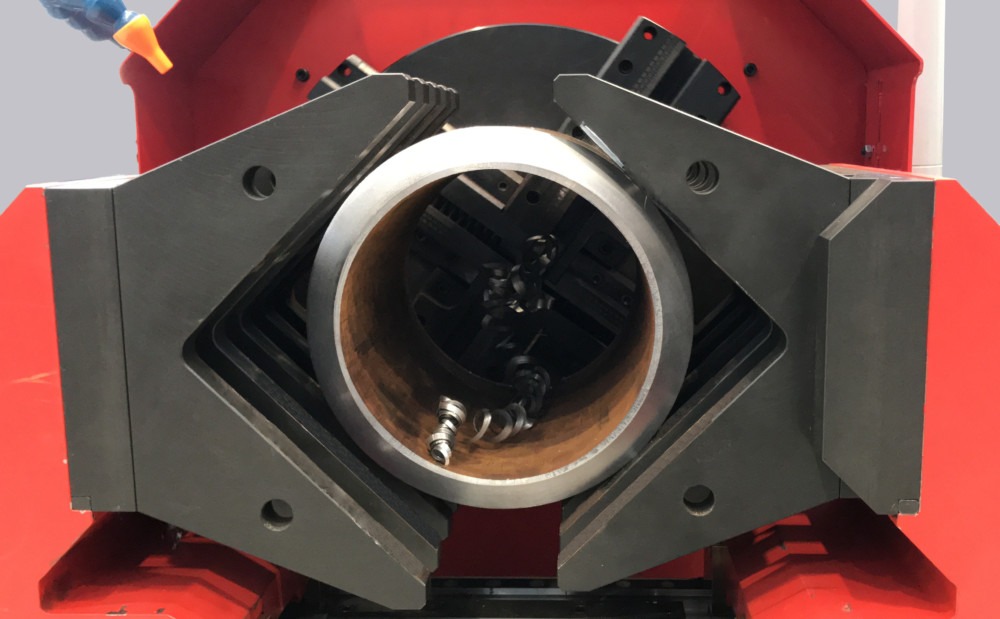

- Chuck with variable configuration, with slots for HSS inserts or carbide tip tools

- Working range: 1 1/2″-12 3/4″

- Onboard control panel for managing all the functions of the machine, the working phases, and the full automatic cycle;

- Self-centering and deformation-free prismatic jaws with automatic tightening torque sensor;

- Automatic pipe positioner;

- Onboard automatic lubricating system;

- Chuck with variable configuration, with seats for HSS inserts or carbide tip tools

Technical Data

| Od Locking Range mm (inches) | 33.4 ÷ 323.9 (1.31” ÷ 12.75”) |

| Voltage (V) | 400 |

| Chuck Motor Power (KW) | 5.5 |

| Chuck Max Torque Nm | 2100 |

| Cooling Liquid Pump Motor Power (KW) | 0.24 |

| Feeding Motor Power (KW) | 0.18 |

| Locking Jaws Unit Motor Power (KW) | 0.37 |

| Pipe Positioner Motor Power (KW) | 0.022 |

| Total Power (KW) | 6.3 |

| Head Feeding Stroke mm (inches) | 140 (5.51) |

| Max Feeding Speed mm/min (inches/min) | 34 (1.33) |

| Idle Speed (Rpm) | 0 ÷ 23 |

| Machine Weight kG | 1650 |

Reviews

There are no reviews yet