Description

Sifmig 328 MIG Brazing Wire – 1 mm x 12.5 Kg

The Sifmig 328 MIG Brazing Wire, with a diameter of 1.0mm and weighing 12.5 Kg, is a premium 92/8 aluminium bronze wire. It is meticulously crafted for welding materials that have a similar composition, especially copper alloys. This wire stands out for its suitability in MIG Brazing, particularly for dissimilar metal joints and various maintenance applications. Its unique composition makes it a top choice for creating wear-resistant surfaces, especially in areas with relatively light loads. Furthermore, it offers commendable resistance against corrosive media, notably salt.

Key Features:

- Aluminium Bronze Composition: Contains 92% copper and 8% aluminium, ensuring compatibility with similar materials and copper alloys.

- MIG Brazing Speciality: Specifically designed for MIG Brazing dissimilar metal joints and maintenance tasks.

- Corrosion Resistance: Offers a robust resistance to corrosive agents, such as salt.

- Welding Flexibility: Can be welded in various positions, catering to a wide range of industries and applications.

- Pre-Heat Consideration: Depending on the material’s thickness and its aluminium content, there might be a need for a slight pre-heat or warming before brazing.

Typical Applications:

The Sifmig 328 MIG Brazing Wire finds its use in a plethora of applications, including:

- Ship Building and Offshore Industries: Ideal for structures and components that demand corrosion resistance.

- Power Generation: Suitable for components that require wear resistance and longevity.

- Repair and Maintenance: Particularly beneficial for maintaining car parts, tools, and other machinery.

- Chemical Industry: Perfect for equipment and structures exposed to corrosive chemicals.

- Automotive and Tools: Especially useful for car parts, tools, bearings, and galvanized steel sheets.

- Aluminium Bronze Alloys: Specifically designed for welding certain aluminium bronze alloys, ensuring a high-quality weld and strength.

Basic Data

| Application | MIG Welding |

| Sub Category | Mig Wire – Brazing |

| Part Number | WO321012A |

| Weight | 12.5 KG |

| Diameter | 1.0mm |

| Melting Point DegC | 1030 |

| U.T.S. N/mm2 | 430 |

| Current Amps | 40-220 |

| Current DC | + |

| Shielding Gas | Pure Argon (0-15 Ipm) |

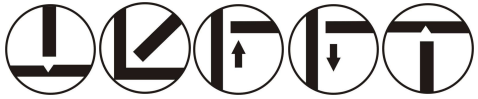

Welding Positions

Suitable for use in the ship building and offshore industries, power generation, repair and maintenance, and the chemical industry.

Particularly useful in the maintenance of car parts and tools, bearings in general, and galvanized steel sheets.

Typical Metal Weld Composition

| Al | 8% |

| Cu | Bal |

Typical Mechanical Properties

| Melting Point | 1030°C |

| Ultimate Tensile Strength | 430 N/mm² |

| Hardness | 85 |

Material to be Welded

Can be used on aluminium bronze alloys: CuAl8 Fe3, CuAl10 FeMn2, CuAl9 Mn9 and cast aluminium bronzes G-CuAl8, G-CuAl10Ni.

A small amount of pre-heat/warming may be required prior to brazing, depending on the material thickness and aluminium content.

Standards

| EN 14640 | Cu 6100 (CuAl8) |

| BS 2901 | C28 |

| AWS A5.7 | ERCuAl-Al |

Reviews

There are no reviews yet