Description

Hardfacing MIG Wire 1.2 mm Sifcored 600 – 15 Kg

The Sifcored 600 Hardfacing MIG Wire is a gas-shielded, tubular cored wire designed specifically for high wear resistance. It’s crafted for the MIG welding process and is ideal for applications that demand both impact and abrasion resistance. This metal cored wire is perfect for wear-resistant surfacing of steel, cast steel, and high Mn steel that are exposed to conditions like abrasion, metal-to-metal wear, impact, and compression stresses.

Key Features:

- Gas-Shielded: Ensures a cleaner weld with reduced spatter and better protection against atmospheric contamination.

- Tubular Cored: Provides consistent and smooth wire feed, leading to uniform welds.

- High Wear Resistance: Designed to withstand abrasive conditions, ensuring longevity of the welded parts.

Typical Applications:

The Sifcored 600 Hardfacing MIG Wire is commonly used in:

- Earthmoving and Quarry Industries: Ideal for hardfacing digger buckets, crusher hammers, and blades.

- Agricultural Sector: Used on equipment like ploughshares to increase their lifespan.

- Overlay Tasks: For building up worn-out parts or adding a protective layer to prevent wear.

- General Hardfacing: Any application where a surface needs to be made more resistant to wear, especially on mild and medium tensile steels.

Specifications

| Product Type | Mig Wire – Hardfacing |

| Part Number | WO601215 |

| Weight | 15 KG |

| Diameter | 1.2 mm |

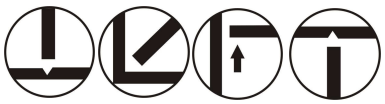

Welding Positions

Typical Mechanical Properties

| Melting Point | 1450°C |

| Ultimate Tensile Strength | n/a N/mm² |

| Hardness | 570-650 |

Typical Weld Metal Composition

| C | 0.5% |

| Si | 1% |

| Mn | 1.5% |

| Cr | 5% |

Material to be Welded

Most frequently used on mild and medium tensile steels.

Before welding, it’s crucial to ensure that the areas to be hardfaced are clean and free from contaminants like oil, grease, and dirt. Additionally, any base metal showing signs of cracking or previous hardfacing should be adequately removed to achieve the best results.

Standards

| DIN 8555 | MSG6-4Z-60 |

Reviews

There are no reviews yet