Description

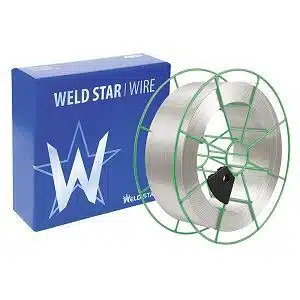

SIFMIG 5356 – Aluminium MIG Wire – 1.0 mm x 2 Kg

SIFMIG 5356 is a general-purpose aluminium MIG wire, enriched with 5% magnesium. This composition provides the wire with excellent corrosion resistance and high strength. It’s designed for welding magnesium-bearing aluminium alloys and certain heat-treatable alloys. The wire is precision layer-wound, ensuring positive and uninterrupted feeding, making it ideal for both semi-automated and fully-automated welding systems.

Features & Benefits:

- Magnesium Enriched: Contains 5% magnesium, enhancing corrosion resistance and strength.

- Precision Layer Wound: Ensures consistent and uninterrupted feeding during the welding process.

- Versatility: Suitable for welding a range of aluminium alloys and components. It can also be used for welding components that will be anodised later.

- High Strength: Offers a high ultimate tensile strength of 250 N/mm².

Common Applications:

- Welding magnesium-bearing aluminium alloys like 5251 (N4), 5154 (N5), and 5454 (N51).

- Suitable for heat-treatable alloys such as 6063 (H9), 6061 (H20), and 6082 (H30).

- Welding of forged and cast aluminium-manganese/aluminium-magnesium components.

- Welding dissimilar aluminium alloy grades with up to 5% Mg.

- Applications where the welded component will be anodised.

Material To Be Welded

Suitable for welding magnesium bearing aluminium alloys such as 5251 (N4), 5154 (N5), 5454 (N51) and also heat treatable alloys 6063 (H9), 6061 (H20) and 6082 (H30). Also suitable for welding forged and cast aluminium-manganese / aluminium-magnesium components, and dissimilar aluminium alloy grades containing a maximum of 5% Mg. Can also be used to weld components which are to be subsequently anodised.

Pre-heating up to 1200 degC may be necessary, subject to material size and thickness. Wire brushing between passes is recommended to ensure removal of surface oxide build up.

Suitable for use on plate, pipe, tube and components. Ensure that parent metal surface is cleaned and fully degreased prior to welding.

Welding Positions

Typical Weld Metal Composition

| Mg | 5 % |

| Al | Bal |

Typical Mechanical Properties

| Melting Point | 640°C |

| Ult Tensile Strength | 250 N/mm² |

| Hardness | 60 |

Basic Data

| Part Number | WO270805 |

| Weight | 0.5 KG |

| Diameter | 0.8mm |

| Melting Point ( degC) | 640 |

| U.T.S. (N/mm²) | 250 |

| Current | DC=+ |

| Shielding Gas | Argon, Argon/Helium |

Standards

| EN ISO 18273 | S Al 5356 (AlMg5) |

| BS 2901 | 5356 (NG6) |

Reviews

There are no reviews yet