Pipe clamps are essential tools for welding and fabrication projects. They are used to hold pipes and tubes in place during pipe welding, cutting, and fitting. Different types of pipe clamps are available to suit various applications, and it is important to choose the right type of clamp for the job. In this article, we will discuss the various types of pipe clamps that can be used in welding and fabrication, including cage clamps and alignment clamps. We will also examine the features, benefits, and recommended uses of each type of clamp to help you choose the right one for your project.

In this guide:

Huge Savings on Pipe Clamps

We offer a wide range of pipe alignment clamps designed to meet the needs of welding professionals and enthusiasts alike.

Chain Clamps

Chain clamps are a popular tool for welding and fabrication that provide a secure and stable hold on pipes during welding. They come in a variety of designs and sizes to accommodate different pipe diameters and wall thicknesses and can be made from various materials to suit specific applications.

Chain clamps are welding tools that use chains to hold pipes together. They consist of a series of interconnected chain links that can be adjusted to fit around the circumference of the pipe. Chain clamps are commonly used in applications that require a high degree of alignment accuracy, such as in the construction of large pipelines or in the fabrication of structural steel.

Chain clamps come in various designs and sizes to accommodate different pipe diameters and wall thicknesses. The most basic design of a chain clamp consists of a set of jaws that attach to the chains and grip the pipe. The jaws can be adjusted using threaded screws to accommodate different pipe diameters.

Chain clamps offer several benefits for welding and fabrication. They provide a secure and stable hold on the pipe, which can help to ensure proper alignment during welding. Additionally, chain clamps can be easily adjusted to accommodate different pipe sizes, making them a versatile tool for a variety of welding applications.

There are several variations in the design and materials used in chain clamps. Some chain clamps feature a spring-loaded design that allows for quick and easy adjustment of the jaws. Others may have a swivel feature that allows for greater flexibility in positioning the clamp on the pipe. Chain clamps can also be made from various materials, including aluminium, steel, or even plastic, depending on the specific application and environment in which they will be used.

Cage Clamps

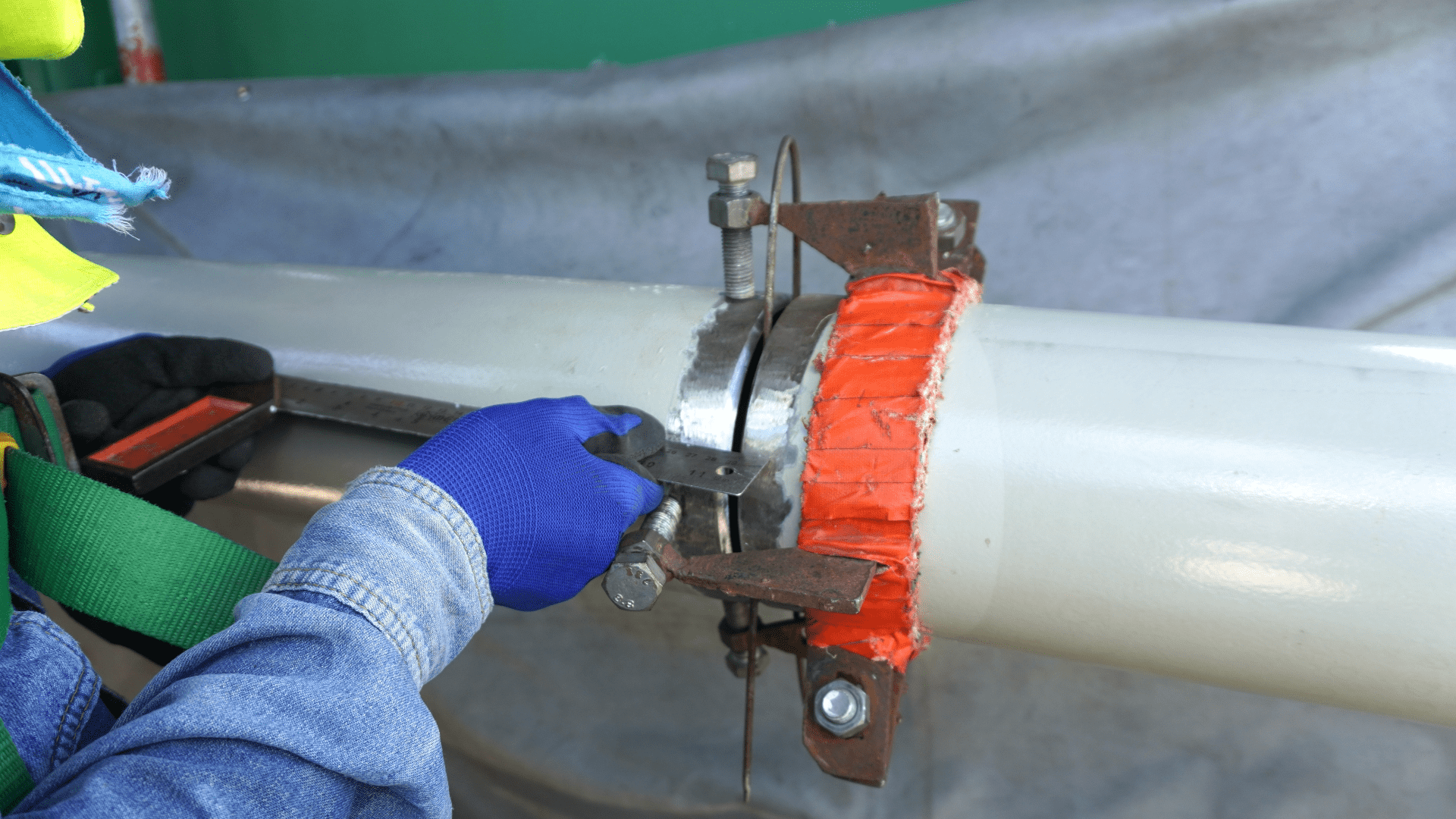

Cage clamps are an essential tool for welding and fabrication tasks that involve cylindrical objects with large diameters. With their ability to hold objects securely in place and provide even pressure distribution, they are a valuable addition to any welder or fabricator’s toolkit.

Cage clamps are a type of pipe clamp that are specifically designed to hold together cylindrical objects with large diameters, such as tanks or pipes. They are ideal for welding and fabrication tasks that involve these types of objects.

Cage clamps are typically made from high-quality steel, and they come in various designs and sizes. One common design features a series of chains that surround the cylindrical object and then connect to a central point. This design allows for even pressure distribution and a secure hold. Another common design features a series of adjustable clamps that can be tightened around the object.

One of the main benefits of cage clamps is their ability to hold cylindrical objects securely in place during welding or fabrication. They also provide consistent pressure around the entire circumference of the object, which can help to prevent warping or distortion during the welding process.

There are many variations in the design and materials of cage clamps. Some are made from steel, while others are made from aluminium or other metals. Some cage clamps feature adjustable jaws that can be moved to accommodate different diameters, while others are designed for use with specific pipe sizes.

Cage clamps are commonly used in a variety of industries, including construction, shipbuilding, and oil and gas. They are also commonly used in the fabrication of large-scale industrial equipment and machinery.

Scissor Pipe Clamps:

Scissor pipe clamps are a useful tool for welding and fabrication, providing a secure and versatile way to hold pipes in position for welding.

Scissor pipe clamps are commonly used in welding and fabrication for holding pipes in position during welding. They are designed to provide a secure grip on the pipe, preventing it from slipping or moving during the welding process.

Scissor clamps work by using two jaws that grip the pipe on either side, with a screw mechanism to tighten the grip. The jaws are designed to provide a strong, even grip on the pipe without causing any damage.

One advantage of scissor pipe clamps is their versatility. They can be used with pipes of varying sizes and shapes, and they are also suitable for use with non-circular pipes such as square or rectangular tubes. They are also portable and easy to use, making them a popular choice for field work or on-site welding.

When using scissor pipe clamps, it is important to ensure that the clamps are properly sized for the pipe being held. Using the wrong size clamp can result in slippage or damage to the pipe. It is also important to ensure that the clamps are properly tightened to prevent any movement during welding.

Spider Pipe Clamps

Spider pipe clamps are another popular type of pipe clamp used in welding and fabrication. They are typically used for aligning and holding pipes in place during welding, cutting, or other fabrication processes. Spider clamps are made up of multiple jaws that can be adjusted to fit pipes of different diameters. These clamps are commonly used in the oil and gas industry, as well as in HVAC and plumbing applications.

One of the benefits of spider pipe clamps is their versatility. They can be used on both horizontal and vertical pipes, and can even be used on pipes that are at odd angles. The multiple jaws on the clamp allow for a secure grip on the pipe, preventing it from slipping or moving during the welding process.

However, it is important to note that spider pipe clamps should not be used on thin-walled pipes or pipes that are highly susceptible to distortion. This is because the pressure from the multiple jaws on the clamp can cause deformation in the pipe. In these cases, other types of clamps, such as cage clamps, may be more suitable.

When using spider pipe clamps, it is important to ensure that the clamp is properly aligned with the pipe to avoid any additional stress on the pipe. Additionally, the clamp should be tightened gradually and evenly to prevent damage to the pipe.

Overall, spider pipe clamps are a versatile and effective tool for holding pipes in place during welding and fabrication processes. However, it is important to consider the type and thickness of the pipe being worked on to ensure that the clamp is being used appropriately.

Linear Pipe Clamps

Linear pipe clamps are used to align and secure pipes in a straight line. They are ideal for welding and fabrication projects where precision is critical. These clamps come in various sizes and designs, and some can hold multiple pipes simultaneously.

Linear pipe clamps typically have a set of jaws that clamp onto the pipes and a mechanism for tightening the clamps securely. They can also have levelling screws or adjustment features to ensure that the pipes are held in a perfectly straight line.

Linear pipe clamps are commonly used in large-scale welding projects, such as those in the oil and gas industry or shipbuilding. They are also used in smaller projects, such as plumbing or HVAC installations, where straight and aligned pipes are essential for proper function.

One advantage of linear pipe clamps is that they can be used to hold pipes of different sizes and shapes, including square, rectangular, and round pipes. They can also be used in different positions, such as horizontal, vertical, or overhead.

When selecting linear pipe clamps, it is important to choose the right size and design for the pipes being used. It is also crucial to follow the manufacturer’s instructions for proper use and maintenance to ensure that the clamps function effectively and safely.

Screw Clamps

Screw clamps are a versatile and widely used type of pipe clamp in welding and fabrication. Their adjustability and various designs and materials make them suitable for a wide range of applications.

Screw clamps, also known as worm gear clamps, are widely used in welding and fabrication. They consist of a band or strap that wraps around the pipe and a screw mechanism that tightens the band around the pipe. The screw mechanism is usually located on the side of the clamp and can be adjusted to apply the desired level of pressure.

Screw clamps are often used for holding pipes and tubes in place during welding and fabrication. They provide a secure grip on the pipe and can be tightened to the desired level of pressure. This makes them ideal for holding pipes and tubes in place while welding or cutting them to size. Screw clamps are also commonly used in plumbing and automotive applications.

One of the main benefits of screw clamps is their adjustability. The screw mechanism allows the user to adjust the clamp’s pressure to the exact level needed for the task at hand. This makes them very versatile and suitable for a wide range of applications.

Screw clamps come in various designs and materials. Some designs have a narrow band or strap, while others have a wider band for greater surface area contact with the pipe. Some screw clamps have a simple screw mechanism, while others have a ratcheting mechanism that allows for easier tightening.

Screw clamps can be made from a variety of materials, including stainless steel, aluminium, and plastic. Stainless steel clamps are very durable and can withstand high levels of pressure and heat, making them ideal for welding applications. Aluminium clamps are lightweight and easy to handle, while plastic clamps are affordable and resistant to corrosion.

Other Types of Clamps

In addition to the popular welding and fabrication clamps discussed above, there are a variety of other clamps that can be used for specialized applications. These clamps can be used to securely hold and align workpieces during welding, or to provide a stable platform for cutting and grinding operations. The table below gives a brief overview of other types of clamps and their uses:

| Clamp Type | Use |

| C-Clamp | Used to hold together two workpieces during welding, drilling or machining |

| F-Clamp | Used to hold two workpieces together when welding or machining |

| Locking Pliers | Used to hold workpieces that are difficult to clamp |

| Spring Clamp | Used to hold lightweight workpieces together |

| Bar Clamp | Used to hold large or bulky workpieces together |

| Magnetic Clamp | Used to hold metal workpieces in place during welding or machining |

| Toggle Clamp | Used to hold workpieces in place during drilling, welding or machining |

In conclusion, there are various types of pipe clamps available for welding and fabrication projects, each with its own unique features and benefits. Cage clamps are ideal for holding pipes in position during welding, while alignment clamps are perfect for aligning pipes before welding.

Other popular types of pipe clamps include chain clamps, screw clamps, and saddle clamps, all of which offer their own advantages depending on the specific needs of the project.

When selecting a pipe clamp, it’s essential to consider factors such as the pipe’s diameter and material, the welding process, and the desired level of accuracy and precision. By choosing the right clamp for the job, welders and fabricators can ensure that their projects are completed efficiently, safely, and to the highest possible standards.

To use pipe clamps effectively, it’s crucial to follow the manufacturer’s instructions carefully and take necessary safety precautions, such as wearing protective gear and avoiding over-tightening the clamp. By using pipe clamps correctly, welders and fabricators can achieve excellent results and create high-quality, reliable products that meet or exceed their clients’ expectations.