Welding electrode ovens and quivers are essential tools for proper storage and handling of welding electrodes. Welding electrodes are susceptible to moisture and humidity, which can cause them to lose their effectiveness and lead to welding defects. Using welding electrode ovens and quivers can help prevent these issues by providing a controlled environment for storing and maintaining welding electrodes.

In this guide, we will provide an overview of welding electrode ovens and quivers, their benefits, and how to use them. We will also discuss the importance of proper storage and handling of welding electrodes and provide tips for maintaining and caring for welding electrode ovens and quivers. By the end of this guide, you will have a better understanding of how welding electrode ovens and quivers can improve the quality and efficiency of your welding projects.

In this guide:

Huge Savings on Electrode Ovens!

We offer a range of Welding Electrode Quivers and Ovens designed to meet the needs of professionals across various industries.

What are welding electrode ovens?

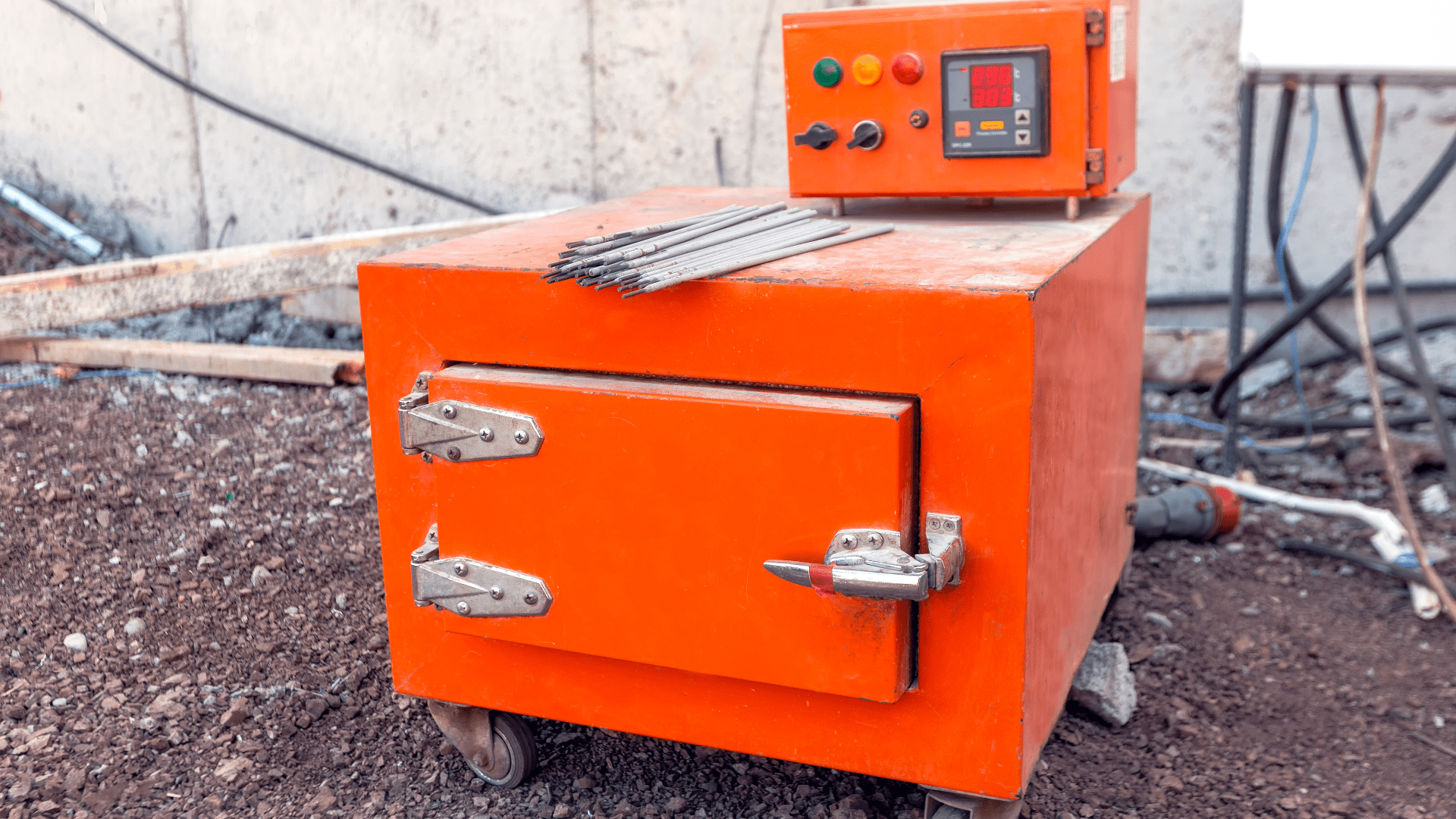

Welding electrode ovens are devices used to store and maintain welding electrodes at a controlled temperature and humidity level. The ovens typically use a heating element to maintain a consistent temperature and a fan to circulate the air and prevent moisture buildup. Welding electrode ovens come in various sizes and designs, with some being portable and others designed for stationary use in a welding shop.

The primary purpose of welding electrode ovens is to keep the electrodes dry and prevent them from absorbing moisture from the air, which can lead to welding defects such as porosity and cracking. Welding electrode ovens are particularly useful when working in humid environments or when welding with electrodes that are prone to moisture absorption.

Some of the benefits of using welding electrode ovens include:

- Preventing welding defects caused by moisture

- Improving the performance of welding electrodes

- Extending the shelf life of welding electrodes

- Reducing waste and cost by preventing the need to discard damaged electrodes

Different types of welding electrode ovens include portable ovens, bench-top ovens, and floor-standing ovens. Portable ovens are ideal for on-site welding projects, while bench-top ovens and floor-standing ovens are suitable for use in a welding shop.

What are welding electrode quivers?

Welding electrode quivers are another type of device used to store and maintain welding electrodes. Unlike welding electrode ovens, which use heat to maintain a controlled temperature, quivers use airtight containers to prevent moisture from entering and contaminating the welding electrodes. Quivers are typically made of durable materials, such as plastic or metal, and come in various sizes and designs.

The primary purpose of welding electrode quivers is to keep the welding electrodes dry and prevent them from absorbing moisture, which can lead to welding defects. Quivers are particularly useful when working in humid environments or when welding with electrodes that are prone to moisture absorption.

Some of the benefits of using welding electrode quivers include:

- Preventing welding defects caused by moisture

- Improving the performance of welding electrodes

- Extending the shelf life of welding electrodes

- Reducing waste and cost by preventing the need to discard damaged electrodes

Different types of welding electrode quivers include vacuum-sealed quivers, screw-top quivers, and hinged-lid quivers. Vacuum-sealed quivers provide the most airtight storage environment, while screw-top and hinged-lid quivers are more convenient to use.

Why use welding electrode ovens and quivers?

Proper storage and handling of welding electrodes is critical to the quality and efficiency of welding projects. Welding electrodes that have been exposed to moisture or humidity can cause welding defects, such as porosity, cracking, and hydrogen-induced cracking. These defects can weaken the integrity of the weld, compromise the safety of the finished product, and result in increased costs due to rework or rejection of the weld.

Using welding electrode ovens and quivers can help prevent welding defects caused by moisture and ensure that welding electrodes perform at their best. By keeping the welding electrodes dry and free of contamination, ovens and quivers can improve the quality and efficiency of welding projects and reduce waste and cost by preventing the need to discard damaged electrodes.

Some of the benefits of using welding electrode ovens and quivers include:

- Preventing welding defects caused by moisture and humidity

- Extending the shelf life of welding electrodes

- Improving the performance of welding electrodes

- Reducing waste and cost by preventing the need to discard damaged electrodes

How to use welding electrode ovens and quivers

Using welding electrode ovens and quivers is a straightforward process, but it is important to follow proper procedures to ensure that the welding electrodes are stored and maintained correctly. Here are some steps to follow when using welding electrode ovens and quivers:

- Check the condition of the welding electrodes before placing them in the oven or quiver. Discard any electrodes that show signs of damage, such as rust, corrosion, or bending.

- Preheat the oven to the recommended temperature for the type of welding electrode being used. The temperature range will vary depending on the type of electrode and manufacturer’s recommendations.

- Place the welding electrodes in the oven or quiver and close the lid securely. For ovens, make sure the fan is running to circulate the air and prevent moisture buildup.

- Monitor the temperature and humidity level of the oven or quiver regularly to ensure that they remain within the recommended range.

- When you are ready to use the welding electrodes, remove them from the oven or quiver and allow them to acclimate to room temperature before use.

To maintain and care for welding electrode ovens and quivers, follow these tips:

- Clean the inside and outside of the oven or quiver regularly to prevent contamination.

- Check the temperature and humidity levels regularly to ensure they are within the recommended range.

- Store the oven or quiver in a dry, cool place when not in use.

- Inspect the oven or quiver regularly for signs of damage or wear and replace it if necessary.

Safety considerations when using welding electrode ovens and quivers

While welding electrode ovens and quivers are relatively safe to use, there are some safety considerations to keep in mind to ensure that you use them safely and avoid injury or damage. Here are some safety tips to follow when using welding electrode ovens and quivers:

- Follow the manufacturer’s instructions for use and maintenance of the oven or quiver.

- Do not exceed the maximum capacity of the oven or quiver. Overcrowding the oven or quiver can affect the airflow and temperature control, leading to inadequate drying or heating.

- Always use heat-resistant gloves when handling hot welding electrodes or opening a hot oven or quiver.

- Do not touch the heating element or fan of the oven while it is in operation.

- Store the oven or quiver in a safe place away from flammable materials or sources of heat.

- Do not attempt to repair or modify the oven or quiver yourself. Contact a qualified technician or the manufacturer for repairs or maintenance.

Choosing the Right Electrode Oven or Quiver

When it comes to purchasing an electrode oven or quiver, there are several considerations to keep in mind. In this guide, we will discuss the important factors to consider when buying an electrode oven or quiver.

- Capacity and Size: The first consideration when purchasing an electrode oven or quiver is the capacity and size. The capacity of the oven or quiver determines the number of welding electrodes that can be stored and maintained at a given time. It is important to choose an oven or quiver that can accommodate the number of electrodes you typically use for your welding projects. The size of the oven or quiver should also be suitable for your workspace and storage area.

- Temperature Control: Temperature control is an important consideration when purchasing an electrode oven. Different types of electrodes require different storage temperatures. Therefore, it is crucial to choose an oven that has a temperature control system to ensure that the electrodes are stored at the appropriate temperature. Some electrode ovens have a digital display that allows for precise temperature control, while others have a manual thermostat that requires frequent monitoring.

- Humidity Control: Humidity control is another critical consideration when purchasing an electrode oven or quiver. Welding electrodes are sensitive to moisture and humidity, which can cause them to lose their effectiveness and lead to welding defects. It is essential to choose an oven or quiver that has a humidity control system to prevent moisture buildup and ensure that the electrodes remain dry.

- Mobility: The mobility of the electrode oven or quiver is an important factor to consider, especially if you need to move the equipment from one job site to another. Portable electrode ovens are suitable for on-site welding projects, while stationary ovens are suitable for welding shops. Some electrode quivers are designed to be worn on a belt, allowing the welder to have easy access to the electrodes.

- Durability: Durability is an essential consideration when purchasing an electrode oven or quiver. Welding equipment is subjected to harsh environments and can be prone to damage if not designed with durability in mind. Choose an oven or quiver made from durable materials that can withstand the rigors of welding.

- Cost: The cost of an electrode oven or quiver is an important consideration. The price of the equipment will depend on the size, features, and brand. It is essential to choose an oven or quiver that fits your budget without compromising the quality and performance of the equipment.

- Brand and Warranty: The brand and warranty of an electrode oven or quiver are also important considerations. Choose a reputable brand that has a proven track record in the industry. A good warranty ensures that you can get support or replacement for the equipment in case of defects or malfunctions.

In conclusion, purchasing an electrode oven or quiver is an essential investment for any welding project. It is crucial to consider factors such as capacity, temperature control, humidity control, mobility, durability, cost, brand, and warranty when purchasing an electrode oven or quiver. By considering these factors, you can choose the right equipment that meets your welding needs and helps you achieve high-quality welds.