Understanding TIG Filler Rods

TIG (Tungsten Inert Gas) welding is known for precision and control, but the quality of the weld depends heavily on the filler rod you choose. Each AWS classification tells you what the rod is designed for — from stainless and aluminium to nickel alloys and titanium. Knowing how to read these codes makes it easier to select the right rod for strength, corrosion resistance, or specialised applications.

👉 Explore our full range of TIG Filler Rods to find the perfect match for your project.

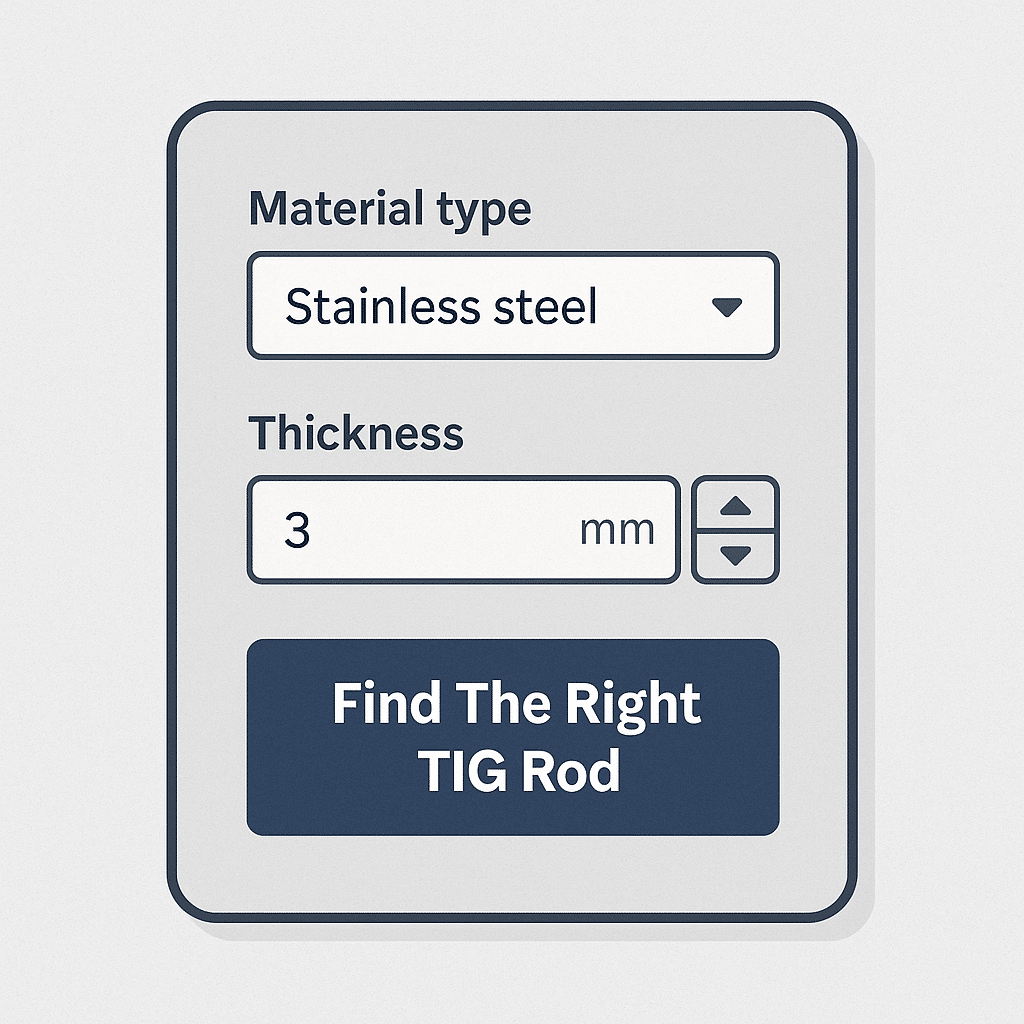

Need Help Choosing the Right TIG Rod?

ake the guesswork out of welding. Use our TIG Rod Selector Tool!

Simply enter your material type and thickness, and we’ll recommend the best wire for the job!

In this guide:

Understanding the roles and importance of TIG filler rods is crucial for anyone involved in TIG welding. As we move forward in this guide, we will discuss different types of TIG filler rods, their characteristics, and their suitable applications, providing valuable information for both novice and experienced welders.

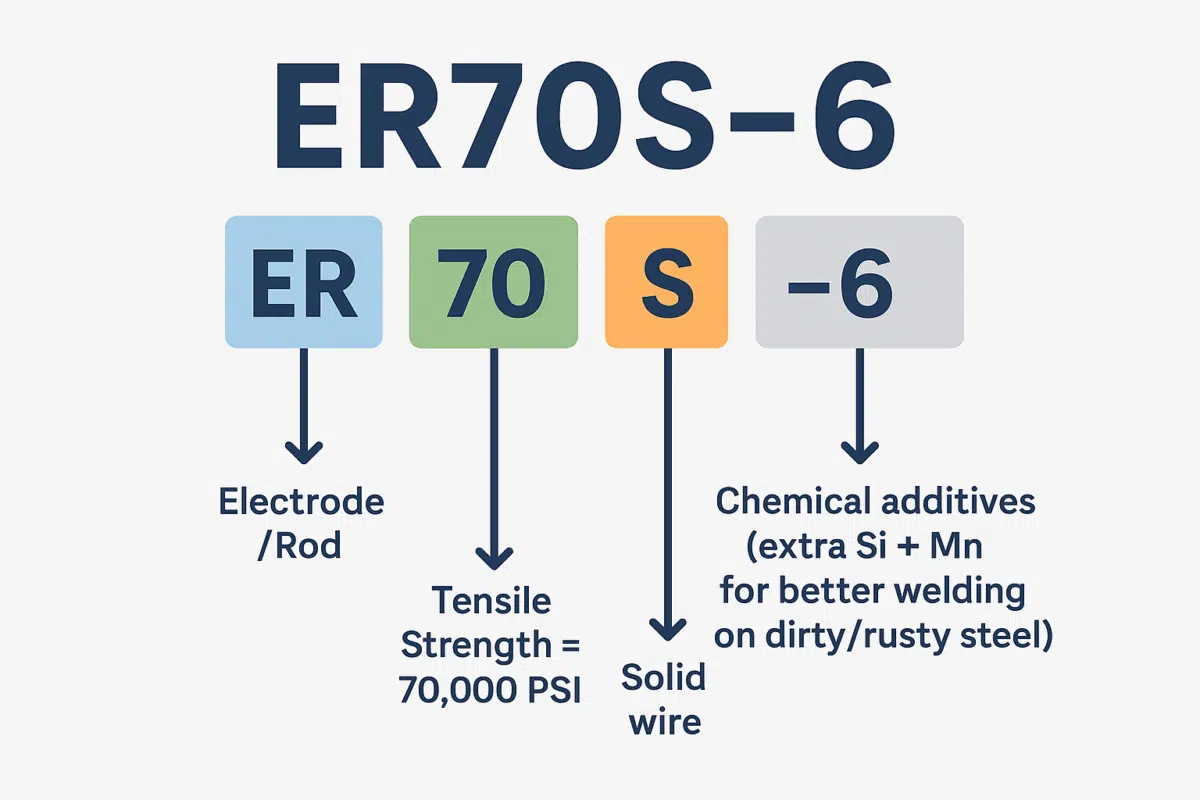

Understanding AWS TIG Filler Rod Codes

The American Welding Society (AWS) created a classification system to make identifying filler rods easier. Once you know how the system works, you can quickly see what a rod is designed for and whether it’s suitable for your job.

How to Read an AWS Code

Example: ER70S-6

- Prefix (ER)

- E = Electrode – the rod can carry current if used as a consumable electrode.

- R = Rod – the filler can be used as a bare rod for TIG welding.

- Together, ER means the rod is suitable for both MIG wire and TIG filler applications.

- Tensile Strength (e.g. 70 in ER70S-6)

- The number shows the strength of the deposited weld metal, in thousands of PSI.

- Example: “70” = 70,000 PSI (about 483 MPa).

- Rod/Wire Type (S)

- S = Solid rod/wire (used for TIG and MIG).

- (Flux-cored and composite codes exist in AWS, but these aren’t relevant to TIG rods.)

- Chemical Additives (e.g. -6, -D2, -L)

- The suffix indicates alloying elements or special properties.

- These affect weld behaviour, shielding gas requirements, corrosion resistance, or high-temperature performance.

Examples of TIG Filler Rod Codes

- ER70S-6 → Solid carbon steel rod, 70,000 PSI strength, with added silicon/manganese for better welds on rusty or dirty steel.

- ER308L → Stainless rod for 304/304L stainless; “L” means low carbon, which helps prevent corrosion.

- ER4043 → Aluminium rod with good fluidity, commonly used on 6XXX alloys (like 6061).

- ER5356 → Aluminium rod with higher strength, widely used on 5XXX alloys (marine/structural).

- ER80S-D2 → High-strength carbon steel rod, with molybdenum added for better toughness at high temperatures.

Why It Matters

Once you understand AWS codes, you don’t have to guess what a filler rod is for — the code tells you:

- What material it matches.

- The strength of the weld deposit.

- Whether it’s a solid rod (always the case for TIG).

- If it has special additives for corrosion resistance, toughness, or heat resistance.

That means choosing the right rod is faster, welds are stronger, and your jobs are more reliable.

High Strength Steel TIG Filler Rods (AWS A5.28)

High strength TIG rods are designed for structural steels, HSLA steels, and applications where higher tensile strength and toughness are required. They’re widely used in construction, pressure vessels, heavy equipment, and aerospace-grade projects.

👉 Browse High Strength TIG Rods to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER80S-D2 | Low Alloy Steel | Mn-Mo rod, for high strength carbon steels in structural and pressure vessel welding. | ≥3 mm – structural & pressure vessels |

| ER100S-G | Low Alloy Steel | High strength, crack-sensitive steels in heavy equipment and structural work. | ≥6 mm – heavy plate/sections |

| ER110S-G | Low Alloy Steel | Higher strength requirements in pressure vessels and construction. | ≥6 mm – heavy sections |

| ER120S-G | Low Alloy Steel | Very high strength steels, aerospace and defense applications. | ≥6 mm – specialty steels |

- General high strength applications → ER80S-D2 is the most common choice.

- Heavy plate/structural work → ER100S-G and ER110S-G provide higher strength where required.

- Aerospace & defense → ER120S-G is reserved for very high strength steels and critical applications.

Hardfacing TIG Filler Rods (AWS A5.13 / A5.21 equivalents)

Hardfacing TIG rods are used to rebuild, protect, and extend the life of components exposed to abrasion, impact, or heat. They are typically applied in industries like mining, quarrying, agriculture, and recycling, where equipment faces constant wear.

👉 Browse Hardfacing TIG Rods to find the best option for your project.

| AWS Code | Alloy Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ERFeMn-A | Manganese steel | High-impact resistance; work hardens in service. | ≥6 mm – crusher jaws, hammers, buckets |

| ERFeCr-A | Chromium carbide | High abrasion resistance in sand, earth, or slurry. | ≥6 mm – augers, chutes, pumps |

| ERFeCr-B | Chromium carbide | Higher Cr for extreme abrasion, less impact resistant. | ≥6 mm – earth-moving, sand handling tools |

| ERFeCr-NbMo | Alloy steel | Severe abrasion + moderate heat resistance. | ≥6 mm – recycling, cement, foundry parts |

- Impact resistance → Manganese rods (ERFeMn) are best for jobs where the part takes repeated hits.

- Abrasion resistance → Chromium carbide rods (ERFeCr grades) give the longest life in abrasive environments.

- Specialist wear → NbMo alloyed rods are used when both heat and abrasion are extreme.

- TIG vs MIG → TIG hardfacing is slower than MIG, but ideal for smaller, precision jobs or repairs.

Aluminium TIG Filler Rods (AWS A5.10)

Aluminium TIG rods are selected based on the alloy series of the base material. They’re widely used in fabrication, automotive, marine, and aerospace applications, offering a balance of strength, corrosion resistance, and weldability.

👉 Browse Aluminium TIG Rods to find the best option for your project.

| AWS Code | Alloy Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER1100 | Pure Al | Welding 1100 & 3003 series; excellent corrosion resistance. | Thin sheet (≥1 mm) up to light plate |

| ER4043 | Al-Si (5%) | 6XXX alloys (6061, 6063); smooth flow, less crack sensitive. | 1 mm sheet up to plate |

| ER4047 | Al-Si (12%) | High silicon, good for castings and wear resistance. | ≥2 mm sheet to plate & castings |

| ER4643 | Al-Si-Mg | Modified 4043 with Mg; stronger welds, popular in automotive body panels. | ≥1 mm sheet |

| ER5183 | Al-Mg | High strength 5XXX (5083, 5456); marine and transport. | ≥2 mm – marine/structural plate |

| ER5356 | Al-Mg | Most common filler; 5XXX (5052, 5086, 5754) and some 6XXX. | 1 mm sheet up to heavy plate |

| ER5554 | Al-Mg | For 5454 alloy in automotive fuel tanks, truck bodies. | ≥2 mm |

| ER5556 | Al-Mg | Stronger than 5356; used in high Mg alloys (5456, 5083). | ≥3 mm – heavy plate |

| ER2319 | Al-Cu | Aerospace-grade, for 2XXX series (2219). | ≥3 mm – heavy plate |

- Most common → ER4043 (smooth flow, less cracking) and ER5356 (higher strength, marine use).

- Automotive → ER4643 and ER5554 are designed for automotive panels and tanks.

- Marine & aerospace → ER5183, ER5556, and ER2319 are used where strength and corrosion resistance are critical.

- Thin sheet (1–2 mm) → 1100, 4043, 5356.

- Heavy plate (≥3 mm) → 5183, 5556, 2319.

Magnesium TIG Filler Rods (AWS A5.19)

Magnesium TIG rods are specialised fillers used for magnesium castings and extrusions. They’re common in aerospace, motorsport, and specialist manufacturing, where lightweight strength and corrosion resistance are essential. Because magnesium is highly reactive, these rods are more niche than aluminium or steel, but critical in the right applications.

👉 Browse Magnesium TIG Rods to find the best option for your project.

| AWS Code | Alloy Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER AZ61A | Mg-Al-Zn | General-purpose filler for wrought magnesium alloys. | ≥2 mm – castings & sheet |

| ER AZ92A | Mg-Al-Zn | High-strength magnesium castings, aerospace parts. | ≥3 mm – heavy castings |

| ER ZK60A | Mg-Zn-Zr | Used in aerospace/military, very high strength alloys. | ≥3 mm – structural plate |

| ER ZK51A | Mg-Zn-Zr | Repairs on cast magnesium components. | ≥2 mm – castings |

- Niche use → Magnesium filler rods are specialised; most welders won’t need them unless working in aerospace, motorsport, or with magnesium castings.

- AZ series (AZ61A, AZ92A) → Most common, used for cast and wrought magnesium.

- ZK series (ZK51A, ZK60A) → High-strength, aerospace-grade applications.

- Care required → Magnesium is highly flammable; TIG is preferred for its control and precision.

Mild Steel TIG Filler Rods (AWS A5.18)

Mild steel TIG rods are used across general fabrication, automotive repair, and pressure vessel applications. They’re available in several grades, each designed to suit different base materials and welding conditions, from clean sheet steel to mill-scaled plate.

👉 Browse Mild Steel TIG Rods to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER70S-2 | Carbon Steel | Triple deoxidised, great for root passes, pipe/tube, and critical welds. | 1.5 mm sheet up to heavy plate |

| ER70S-3 | Carbon Steel | For clean steels in general fabrication. | 1.5 mm sheet to plate |

| ER70S-6 | Carbon Steel | High Si/Mn content, good for welding on rusty or mill-scaled steel. | 1 mm sheet up to heavy plate (25 mm+) |

- General use → ER70S-6 is the most common, reliable for fabrication on less-than-clean steel.

- Pipe & root passes → ER70S-2 is preferred in TIG pipe welding for clean, sound roots.

- Clean fabrication → ER70S-3 works well when welding on new or clean steel with minimal mill scale.

Stainless Steel TIG Filler Rods (AWS A5.9)

Stainless TIG rods are matched to the grade of stainless steel being welded to maintain corrosion resistance and mechanical properties. They’re used across food processing, chemical, petrochemical, marine, and general fabrication industries.

👉 Browse Stainless Steel TIG Rods to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER308L | Austenitic SS | Welding 304/304L stainless steels (most common). | 1 mm sheet up to plate |

| ER309L | Austenitic SS | Welding dissimilar metals (stainless to carbon steel). | ≥2 mm sheet to plate |

| ER316L | Austenitic SS | Welding 316/316L; marine and chemical resistance. | 1 mm sheet up to plate |

| ER347 | Stabilised SS | Welding 321/347 stainless; resists carbide precipitation in high-temp service. | ≥2 mm sheet to plate |

| ER2209 | Duplex SS | Welding duplex stainless steels (2205); higher strength + corrosion resistance. | ≥2 mm – marine & offshore |

| ER2594 | Super Duplex SS | Welding super duplex stainless steels (25Cr alloys). | ≥2 mm – heavy sections |

| ER410NiMo | Martensitic SS | Welding 410 stainless steels in power/pressure work. | ≥3 mm – heavy plate |

- General stainless → ER308L is the most common choice for 304/304L.

- Marine/chemical → ER316L offers superior corrosion resistance in aggressive environments.

- Dissimilar joints → ER309L is ideal for joining stainless to mild or carbon steels.

- High-temp service → ER347 resists carbide precipitation, good for petrochemical and exhaust systems.

- Duplex & super duplex → ER2209 and ER2594 are used in offshore, marine, and chemical processing.

- Martensitic → ER410NiMo is used in turbines, valves, and pressure systems requiring wear and corrosion resistance.

Brazing / Bronze TIG Filler Rods (AWS A5.7)

TIG brazing rods are designed for joining metals at lower temperatures than traditional fusion welding. They’re especially useful for thin sheet metal, galvanised steels, and dissimilar joints, where reducing heat input prevents distortion and preserves coatings. Brazing rods are widely used in automotive bodywork, HVAC, and general repair applications.

👉 Browse Brazing & Bronze TIG Rods to find the best option for your project.

| AWS Code | Alloy Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ERCuSi-A | Silicon Bronze | Automotive panels, galvanised steels, HVAC work. | 0.8–3 mm thin sheet |

| ERCuAl-A2 | Aluminium Bronze | Dissimilar joints, wear-resistant overlays. | ≥2 mm sheet and plate |

| ERCuNi | Copper-Nickel | Marine piping, condensers, seawater applications. | ≥2 mm tube/plate |

| ERCuZn-A | Brass/Bronze | General brazing of steels, cast iron, copper alloys. | ≥1.5 mm sheet to plate |

- Body panels & thin sheet → ERCuSi-A (silicon bronze) is the go-to rod, great for galvanised or thin steels.

- Dissimilar joints → ERCuAl-A2 and ERCuZn-A allow joining steels to copper alloys where fusion welding fails.

- Marine & HVAC → ERCuNi is ideal for pipework exposed to seawater and brine.

- Thin sheet advantage → Because brazing runs cooler, it reduces warping and is perfect for sheet metal work.

Copper & Copper-Nickel TIG Filler Rods (AWS A5.7 / A5.7M)

Copper and copper-nickel TIG rods are used in electrical, plumbing, marine, and HVAC applications. They provide excellent corrosion resistance, conductivity, and strength, making them essential for seawater systems, desalination plants, and heat exchangers.

👉 Browse Copper & Copper-Nickel TIG Rods to find the best option for your project.

| AWS Code | Alloy Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ERCu | Copper | General copper welding/repair, electrical conductors. | ≥1.5 mm sheet & plate |

| ERCuSi-A | Silicon Bronze | Galvanised steel, thin sheet, and bronze repairs. | 0.8–3 mm thin sheet |

| ERCuNi | Copper-Nickel | Marine piping, condensers, shipbuilding, seawater service. | ≥2 mm tube/plate |

| ERCuAl-A2 | Aluminium Bronze | Dissimilar joints, wear surfaces, corrosion service. | ≥2 mm sheet/plate |

- General copper work → ERCu is ideal for welding pure copper, often used in electrical and plumbing.

- Silicon bronze (ERCuSi-A) → Popular for thin sheet and galvanised steel (also often classed under brazing).

- Marine service → ERCuNi is the standard choice for seawater piping and heat exchangers.

- Wear/corrosion resistance → ERCuAl-A2 (aluminium bronze) is best when joining copper alloys to steel or for high-wear environments.

Dissimilar Steels TIG Filler Rods (AWS A5.9)

Dissimilar steel TIG rods are designed for joining stainless steels to carbon/mild steels, or for tackling difficult-to-weld materials. They are often used in maintenance, repair, and fabrication jobs where strength, corrosion resistance, or crack resistance are critical.

👉 Looking for the right rod? Browse our full range of Dissimilar TIG Rods to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER309L | Austenitic SS | Joining stainless to carbon/mild steel; overlay work. | ≥2 mm sheet to plate |

| ER309LSi | Austenitic SS | Similar to 309L, but with higher Si for improved wetting and bead appearance. | ≥2 mm |

| ER312 | Austenitic SS | High strength welds, difficult-to-weld steels, crack-resistant. | ≥2 mm sheet/plate |

| ER307 | Austenitic SS | Dissimilar joints, especially high Mn steels; also used for overlays. | ≥2 mm |

- General dissimilar joints → ER309L is the most common choice for stainless-to-carbon steel.

- Better bead appearance → ER309LSi flows more smoothly and gives cleaner welds.

- High strength & crack resistance → ER312 is the go-to when welding unknown or hard-to-weld steels.

- Special cases → ER307 is often used in applications involving Mn steels or for overlays.

Duplex Stainless Steel TIG Filler Rods (AWS A5.9 / A5.34)

Duplex TIG rods are designed for welding duplex stainless steels, which combine high strength with excellent resistance to stress corrosion cracking and pitting. These rods are widely used in offshore, marine, oil & gas, and chemical plant applications where durability and corrosion resistance are critical.

👉 Looking for the right rod? Browse our full range of Duplex Stainless TIG Rods to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER2209 | Duplex SS | Welding 2205 and similar duplex grades. High strength and resistance to chloride stress corrosion. | 2–25 mm |

| ER2594 | Super Duplex SS | Welding 25Cr super duplex stainless steels. Excellent corrosion and mechanical properties. | 2–25 mm |

| ER2307 | Duplex SS | Welding lean duplex stainless steels (e.g. 2304). Good general corrosion resistance. | 2–20 mm |

- General duplex welding → ER2209 is the standard filler rod for 2205 duplex steels.

- Super duplex → ER2594 provides even higher corrosion resistance, ideal for marine and offshore work.

- Lean duplex → ER2307 is suited to applications where cost-effective corrosion resistance and moderate strength are required.

Nickel Alloy TIG Filler Rods (AWS A5.14)

Nickel alloy TIG rods are used where extreme heat, corrosion, or strength demands make stainless or duplex steels unsuitable. They’re essential in aerospace, petrochemical, cryogenic, and power generation industries where durability and resistance to oxidation and stress corrosion cracking are critical.

👉 Looking for the right rod? Browse our full range of Nickel Alloy TIG Rods to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ERNiCr-3 | Nickel Alloy | Welding Inconel 600/601/690, joining dissimilar metals (Ni to steel). | ≥2 mm – plate & pipe |

| ERNiCrMo-3 | Nickel Alloy | Welding Hastelloy C-22/C-276, excellent corrosion resistance. | ≥2 mm – plate, pipe, chemical equipment |

| ERNiFeCr-2 | Nickel Alloy | Welding Inconel 825 and similar Ni-Fe-Cr alloys. | ≥2 mm |

| ERNiCu-7 | Nickel-Copper | Welding Monel alloys (400, K-500), marine and chemical use. | ≥2 mm sheet, pipe & plate |

| ERNiCrMo-10 | Nickel Alloy | Welding C-22, C-276, and other highly corrosion-resistant alloys. | ≥3 mm – aggressive chemical service |

- Inconel welding → ERNiCr-3 is the most common choice for joining Ni-Cr alloys and stainless steels.

- Corrosion resistance → ERNiCrMo grades (like -3, -10) are suited for harsh chemical environments.

- Marine & chemical → ERNiCu-7 (Monel filler) is used for seawater and salt-brine service.

- High-temp/pressure → Nickel fillers retain strength at extreme temperatures, making them vital in aerospace and power generation.

Titanium TIG Filler Rods (AWS A5.16)

Titanium TIG rods are used in industries where light weight, high strength, and corrosion resistance are critical. They’re widely applied in aerospace, motorsport, chemical processing, and marine environments. Titanium rods provide exceptional weld integrity, but require careful gas shielding (usually 100% argon or argon-helium mixes) to prevent contamination.

👉 Looking for the right rod? Browse our full range of Titanium TIG Rods to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ERTi-1 | Titanium | Commercially pure titanium, good corrosion resistance, low strength. | Thin sheet ≥1 mm |

| ERTi-2 | Titanium | Stronger CP titanium, excellent corrosion resistance, chemical processing. | 1–6 mm sheet & plate |

| ERTi-5 | Titanium | Ti-6Al-4V alloy, aerospace, marine, motorsport, high strength. | ≥2 mm – plate, tube, structural |

| ERTi-7 | Titanium | CP titanium with Pd, improved corrosion resistance in reducing acids. | ≥2 mm – chemical/petrochemical piping |

| ERTi-23 | Titanium | Modified Ti-6Al-4V (ELI grade), high toughness at low temps, medical/aerospace. | ≥2 mm – critical structures |

- Commercially pure grades (ERTi-1, -2) → excellent corrosion resistance, lower strength, easier to weld.

- Aerospace/marine (ERTi-5 / Ti-6Al-4V) → highest strength and widely used in demanding applications.

- Chemical service (ERTi-7) → best choice where resistance to acids and chlorides is required.

- Medical/cryogenic (ERTi-23) → extra-low interstitials give higher toughness at low temperatures.

Final Thoughts

Choosing the right TIG filler rod is just as important as perfecting your welding technique. By understanding AWS classifications and matching rods to the base metal, welders can achieve stronger, cleaner, and longer-lasting welds. From stainless and aluminium to titanium and nickel alloys, each filler has a role in tackling specific challenges — whether that’s corrosion resistance, high strength, or wear protection. With the right knowledge, you can select with confidence, improve efficiency, and get the very best from your welds.