MIG welding (Metal Inert Gas), also called Gas Metal Arc Welding (GMAW), is one of the most widely used welding processes. The choice of welding wire plays a key role in determining the strength, appearance, and overall quality of a weld.

The AWS classification system provides a clear framework for identifying and categorising these wires, helping welders choose the right filler for each job. This guide breaks down the system in simple terms, making it easier to understand MIG welding wires and select the best option for your project.

Need Help Choosing the Right MIG Wire?

Take the guesswork out of welding. Use our MIG Wire Selector Tool!

Simply enter your material type and thickness, and we’ll recommend the best wire for the job!

In this guide:

Understanding AWS Welding Wire Codes

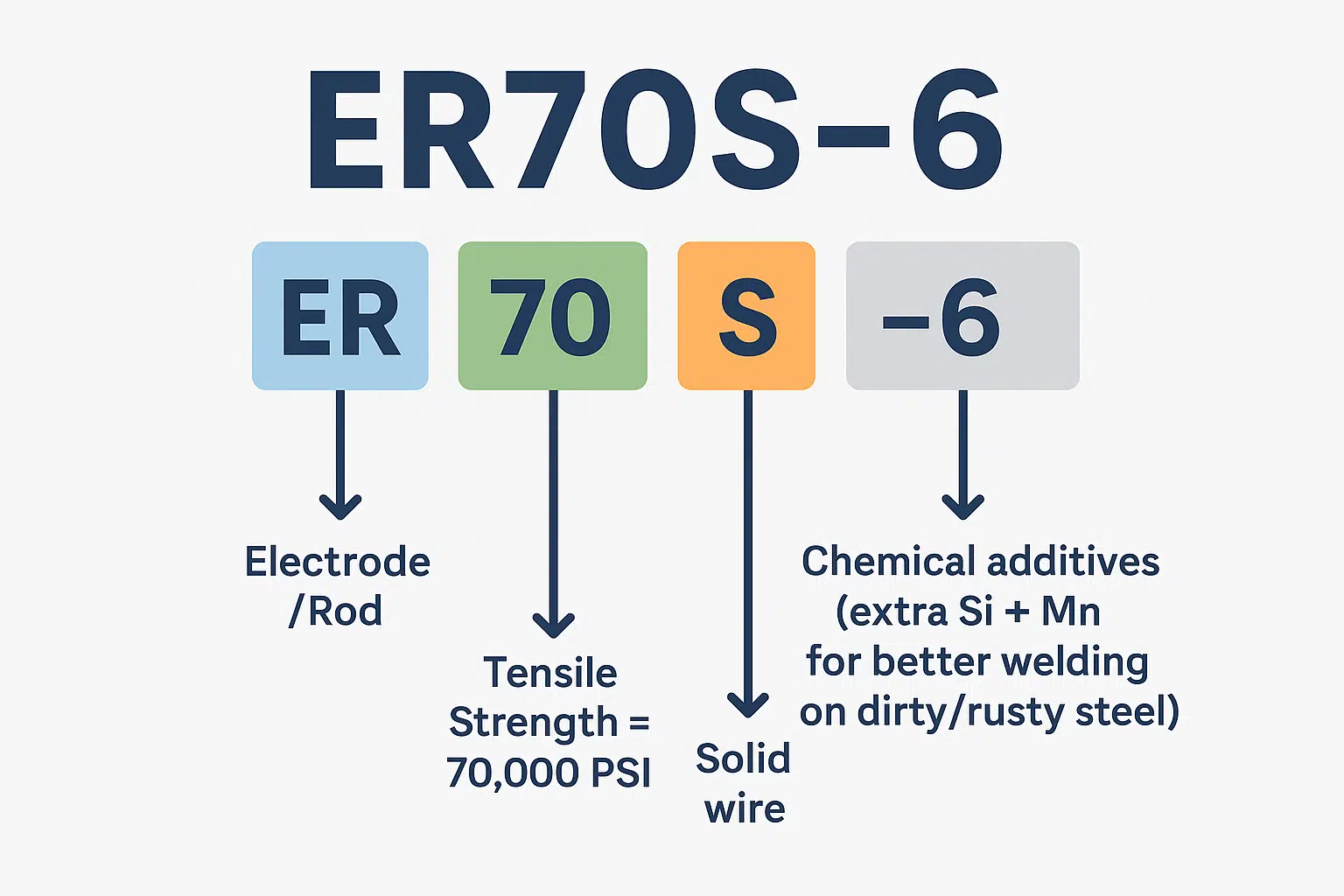

The American Welding Society (AWS) created a code system to make it easier to identify welding wires. Once you know how it works, you can quickly figure out what a wire is designed for and whether it’s right for your job.

How to Read an AWS Code

- Prefix (e.g. ER, E)

- E = Electrode (the wire can carry current).

- R = Rod (the wire can also be used as a rod for TIG).

- Together, ER means the wire can be used as both.

- Tensile Strength (e.g. 70 in ER70S-6)

- The number is the wire’s strength in thousands of PSI.

- Example: “70” = 70,000 PSI (about 483 MPa).

- Wire Type (e.g. S, T, C)

- S = Solid wire.

- T = Tubular/flux-cored wire.

- C = Composite (metal-cored wire).

- Chemical Additives (e.g. -6, -D2, -L)

- The numbers/letters at the end show alloying elements or special properties.

- These affect weld quality, gas requirements, and resistance to cracking or corrosion.

Examples

- ER70S-6 → Solid wire for carbon steel, 70,000 PSI strength, with extra silicon/manganese for welding on rusty or dirty steel.

- ER308L → Stainless steel wire for 304/304L; the “L” means low carbon, which reduces corrosion problems.

- E71T-1 → Flux-cored wire, all-position welding, 70,000 PSI strength. “T” = tubular, “1” = flux type.

- ER4043 → Aluminium wire, good flow, widely used on 6XXX alloys (like 6061).

- ER80S-D2 → Solid wire for higher-strength steels, 80,000 PSI, with molybdenum added for strength at high temperatures.

Why It Matters

Once you get used to the AWS system, you don’t have to guess what a wire is for — the code tells you:

- What material it’s for.

- How strong it is.

- Whether it’s solid, flux-cored, or composite.

- If it has special additives for corrosion resistance, toughness, or high-temperature use.

This means choosing the right wire is quicker, welds are better, and jobs are more reliable.

Common MIG Welding Wire Codes & Charts

Stainless Steel Filler Metals (AWS A5.9 / A5.22)

Stainless steel welding wires are carefully matched to the grade of steel and the demands of the application. The chart below highlights the most common stainless filler wires, their applications, and the typical material thicknesses they’re best suited for.

👉 Browse Stainless Steel MIG Wires to find the right option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| E308LT1-1/-4 | Stainless Steel | Flux-cored wire for welding 301, 302, 304, 305, and 308 stainless steels. | ≥3 mm (1/8″) – plate and structural |

| E309LT1-1/-4 | Stainless Steel | Flux-cored wire for welding dissimilar metals (stainless to carbon/mild steel). | ≥3 mm (1/8″) – plate and overlay work |

| E316LT1-1/-4 | Stainless Steel | Flux-cored wire for welding 316 and 316L stainless steels. | ≥3 mm (1/8″) – plate and heavy sections |

| ER2594 | Stainless Steel | For super duplex stainless steels (25Cr-9Ni-4Mo-N). | 2–25 mm (5/64″–1″) |

| ER307Si | Stainless Steel | Overlay work, welding CMn steels, and dissimilar joints. | ≥2 mm sheet up to plate |

| ER308LSi | Stainless Steel | Welding 304, 304L, 308, and 308L stainless steels. | 1 mm sheet up to plate (25 mm) |

| ER309LSi | Stainless Steel | Welding dissimilar metals (stainless to mild steel) and overlay work. | ≥2 mm sheet to plate |

| ER312 | Stainless Steel | Dissimilar metals, high strength joints, hard-to-weld steels. | ≥2 mm |

| ER316LSi | Stainless Steel | Welding 316 and 316L stainless steels. | 1 mm sheet up to plate |

| ER347 | Stainless Steel | Welding stabilized stainless (321, 347); prevents carbide precipitation. | ≥1.5 mm sheet to plate |

| ER2209 | Duplex Stainless | For duplex stainless steels (22Cr duplex grades). | 2–25 mm |

| ER410NiMo | Martensitic SS | Welding 410 stainless and similar, used in power/pressure applications. | ≥3 mm |

- E codes = flux-cored wires → generally best for medium to heavy plate (≥3 mm).

- ER codes = solid filler rods/wires (MIG/TIG) → suitable from thin sheet (~1 mm) to heavy plate, depending on process.

Carbon & Low Alloy Steel Filler Metals (AWS A5.18 / A5.20 / A5.28)

Carbon and low alloy steel welding wires cover everything from everyday fabrication to high-strength and low-temperature applications. The chart below lists the most widely used options, their applications, and the material thicknesses they’re best suited for.

👉 Browse Steel MIG Wires and find the right wire for your next project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| E70C-6M | Carbon Steel | Metal-cored wire, general fabrication, tolerant to rusty/oily steel. | ≥3 mm – medium to heavy plate |

| E71T-1 | Carbon Steel | All-position flux-cored wire, structural fabrication, shipbuilding. | ≥3 mm – plate and structural |

| E71T-1M | Carbon Steel | All-position flux-cored wire with mixed gas, better on coated steels. | ≥3 mm – plate and structural |

| E81T1-Ni1M-J | Low Alloy Steel | Flux-cored, notch toughness at low temps (–45°C), high strength steels. | ≥6 mm – heavy plate & structural |

| E71T-8 | Carbon Steel | Self-shielded FCAW, field/structural welding, no external gas. | ≥4 mm – heavy sections/structural |

| ER70S-2 | Carbon Steel | Solid wire, triple deoxidized, root passes, critical pipe/tube work. | 1.5 mm sheet up to heavy plate |

| ER70S-3 (added) | Carbon Steel | Solid wire, clean steel welding, general fab (less Si than -6). | 1.5 mm sheet to plate |

| ER70S-6 | Carbon Steel | Solid wire, most common GMAW/TIG rod, high Si for mill scale/rust tolerance. | 1 mm sheet to heavy plate (25 mm+) |

| ER70S-A1 | Low Alloy Steel | 0.5% Mo content, used in high-temp service (boilers, piping). | ≥3 mm – pressure vessels & piping |

| ER80S-D2 | Low Alloy Steel | Mn-Mo wire, welding high strength carbon steels. | ≥3 mm – structural, pressure vessels |

| ER80S-G | Carbon Steel | General-purpose wire for mild and low alloy steels. | ≥2 mm sheet up to plate |

| ER80S-Ni1 | Low Alloy Steel | Ni-alloyed wire, for high impact toughness (–45°C). | ≥3 mm – low temp steels |

| ER80S-Ni2 | Low Alloy Steel | Higher Ni (2%), for very low temp impact toughness (–60°C). | ≥3 mm – cryogenic steels |

| ER80S-B2 (added) | Low Alloy Steel | Cr-Mo steels (1.25Cr-0.5Mo), used in high temp service (power plant piping). | ≥3 mm – thick wall piping |

| ER100S-G | Low Alloy Steel | Welding high strength, crack-sensitive steels. | ≥6 mm – heavy sections |

| ER110S-G | Low Alloy Steel | Higher strength wire, structural and pressure applications. | ≥6 mm – heavy plate |

| ER120S-G | Low Alloy Steel | Very high strength steels, aerospace/defense applications. | ≥6 mm – specialty high strength |

| G3Si1 | Carbon Steel | (European EN ISO equivalent to ER70S-6). General structural welding wire. | 1 mm sheet up to plate |

- E-class (E71T, E70C) → flux-cored or metal-cored wires → best for medium to heavy thicknesses (≥3 mm), high deposition.

- ER-class (ER70S-x, ER80S-x, etc.) → solid wires/rods for MIG/TIG → can weld from thin sheet (~1 mm) to heavy plate.

- Ni-alloyed ER80S wires → specifically for low-temperature toughness.

- Cr-Mo (B2, B3) → for high-temperature creep resistance (power/pressure).

Aluminium Filler Metals (AWS A5.10)

Aluminium welding wires are tailored to the specific series and properties of the alloy—from soft, corrosion-resistant grades to high-strength automotive and aerospace alloys. Below is a chart featuring the most common aluminium filler wires, their typical applications, and the material thicknesses they’re best suited for.

👉 Browse Aluminium MIG Wires to find the perfect wire for your next welding project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER1100 | Aluminium | Pure aluminium wire, welding 1100 and 3003 series, good corrosion resistance. | Thin sheet (≥1 mm) up to light plate |

| ER4043 | Aluminium | High Si (5%), general-purpose for 6XXX series (6061, 6063), good fluidity, less crack sensitive. | 1 mm sheet up to heavy plate |

| ER4047 | Aluminium | Very high Si (12%), good for casting repair, high wear resistance, reduced shrinkage cracking. | ≥2 mm sheet to plate & castings |

| ER4643 (added) | Aluminium | Modified 4043 with Mg, better strength, common in automotive 6XXX body panels. | ≥1 mm sheet |

| ER5183 | Aluminium | High strength, for 5XXX (5083, 5456) and some 6XXX where strength is critical. | ≥2 mm – marine/structural plate |

| ER5356 | Aluminium | Most common filler for 5XXX series (5052, 5652, 5454, 5754, 5086), also usable on 6XXX. | 1 mm sheet up to heavy plate |

| ER5554 (added) | Aluminium | For 5XXX series (5454) in automotive fuel tanks, truck bodies, good corrosion resistance. | ≥2 mm |

| ER5556 | Aluminium | Stronger version of 5356, for high Mg alloys (5456, 5083), marine and structural. | ≥3 mm – heavy plate/structural |

| ER2319 (added) | Aluminium | For high-strength 2XXX series (2219), aerospace/defense use. | ≥3 mm – heavy plate |

- ER4043 vs ER5356 → the two most common.

- 4043 → better flow, less crack sensitive, slightly softer welds.

- 5356 → higher strength, slightly less corrosion resistance in some conditions.

- High Mg wires (5183, 5556, 5554) → used where strength/corrosion are critical (marine, transport, aerospace).

- Thin sheet (1–2 mm) → 1100, 4043, 5356.

- Heavy plate/structural (≥3 mm) → 5183, 5556, 2319.

Flux-Cored Steel Filler Metals (AWS A5.20 / A5.29)

Flux-cored steel wires are widely used for structural fabrication, shipbuilding, and outdoor welding jobs. They offer high deposition rates, good penetration, and in some cases, the ability to weld without shielding gas — making them ideal for everything from workshop production to site work in exposed conditions.

👉 Browse Flux-Cored Steel MIG Wires to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| E70C-6M | Carbon Steel | Metal-cored wire, high deposition, general fabrication, tolerates rust/scale. | ≥3 mm – medium to heavy plate |

| E71T-1 | Carbon Steel | Gas-shielded flux-cored wire, all-position, structural steel, shipbuilding. | ≥3 mm – plate and structural |

| E71T-1M | Carbon Steel | Same as E71T-1 but optimised for mixed gas, good on coated/galvanised steels. | ≥3 mm – plate and structural |

| E71T-8 | Carbon Steel | Self-shielded FCAW, no external gas needed; construction, outdoor/field work. | ≥4 mm – heavy plate and structural |

| E71T-GS | Carbon Steel | Self-shielded, single-pass welding, light fabrication, thin sheet repairs. | 1.2–3 mm thin sheet/patch work |

| E81T1-Ni1 | Low Alloy | Nickel-alloyed flux-cored wire, excellent toughness at low temperatures. | ≥6 mm – heavy structural steel |

| E91T1-B3 | Low Alloy | Flux-cored wire for 2.25Cr-1Mo steels, high-temp/pressure vessel service. | ≥6 mm – power plant/boiler steels |

- General fabrication → E70C-6M or E71T-1 are reliable choices for strong, clean welds on plate.

- Outdoor/site welding → E71T-8 is popular because it doesn’t require shielding gas.

- Thin sheet repairs → E71T-GS is designed for single-pass jobs like auto panels and light metalwork.

- Specialist jobs → Low alloy wires such as E81T1-Ni1 or E91T1-B3 are suited to demanding structural or pressure applications.

Flux-Cored Stainless Steel Filler Metals (AWS A5.22)

Flux-cored stainless wires are designed for welding stainless steels where higher deposition rates and positional capability are needed. They are commonly used in fabrication, maintenance, and repair jobs across food processing, chemical, and petrochemical industries, as well as for joining stainless to carbon steels.

👉 Browse Flux-Cored Stainless MIG Wires to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| E308LT1-1/-4 | Stainless Steel | Welding 301, 302, 304, 305, and 308 stainless steels. | ≥3 mm – plate and structural |

| E309LT1-1/-4 | Stainless Steel | Dissimilar welds (stainless to carbon/mild steel) and overlays. | ≥3 mm – plate and overlay |

| E316LT1-1/-4 | Stainless Steel | Welding 316 and 316L stainless steels, chemical/petrochemical use. | ≥3 mm – plate and heavy sections |

| E347T1-1/-4 | Stainless Steel | Welding stabilized stainless steels (347, 321), heat-resistant. | ≥3 mm – pressure vessels & piping |

| E2209T1-1/-4 | Duplex Stainless | Welding duplex stainless steels (2205), high strength + corrosion. | ≥3 mm – marine, offshore plate |

- General stainless fabrication → E308LT1 is the go-to for most 300-series steels.

- Dissimilar joints → E309LT1 is ideal for welding stainless to mild/carbon steel.

- Chemical/food industry work → E316LT1 is chosen for corrosion resistance in aggressive environments.

- High-temp service → E347T1 is stabilised to resist carbide precipitation, common in heat-resistant stainless.

- Duplex stainless → E2209T1 provides higher strength and chloride stress corrosion resistance, used in offshore, marine, and chemical plants.

Hardfacing Filler Metals (AWS A5.13 / A5.21 equivalents)

Hardfacing wires are designed to extend the life of equipment by depositing wear-resistant surfaces on parts exposed to abrasion, impact, or heat. They’re widely used in industries such as mining, construction, agriculture, and recycling, where components like buckets, blades, and crushers face extreme conditions.

👉 Browse Hardfacing MIG Wires to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ER2209HF | Stainless/Alloy | Multi-purpose hardfacing, good balance of abrasion and impact. | ≥3 mm – overlay and build-up |

| ERFeCr-A | Alloy Steel | Chromium carbide deposits, high abrasion resistance. | ≥6 mm – buckets, chutes, augers |

| ERFeMn-A | Alloy Steel | Manganese steel deposits, resists impact and work hardens in service. | ≥6 mm – crusher jaws, hammers |

| ERFeCr-B | Alloy Steel | Higher Cr content for extreme abrasion, lower impact resistance. | ≥6 mm – sand pumps, earth-moving tools |

| ERFeCr-NbMo | Alloy Steel | Cr + Nb + Mo alloying for severe wear and moderate heat resistance. | ≥6 mm – recycling, cement, foundry tools |

- General wear protection → Multi-purpose wires (e.g. ER2209HF) are a good choice for build-up and moderate abrasion.

- Abrasion resistance → Chromium carbide wires (ERFeCr grades) are best when parts are exposed to sand, earth, or slurry.

- Impact resistance → Manganese-based wires (ERFeMn) excel in high-impact jobs and will harden with use.

- Specialist jobs → Nb/Mo alloyed wires are designed for the toughest wear and heat environments, such as cement or recycling plants.

Brazing Filler Metals (AWS A5.7)

Brazing wires are used to join thin sheet metals at lower temperatures than conventional welding. They are especially popular in automotive repair and manufacturing, HVAC, and galvanised sheet applications, where controlling distortion and preserving coatings is essential. Instead of melting the base metal, brazing wires create a strong metallurgical bond through capillary action, giving cleaner results with less heat input.

👉 Browse Brazing MIG Wires to find the best option for your project.

| AWS Code | Metal Type | Common Applications | Typical Material Thickness |

|---|---|---|---|

| ERCuSi-A | Copper-Silicon | Automotive panel repair, galvanised steel, HVAC components. | 0.8–3 mm thin sheet |

| ERCuAl-A2 | Copper-Aluminium | Joining steel to copper alloys, wear-resistant surfacing. | ≥2 mm sheet and plate |

| ERCuNi | Copper-Nickel | Marine piping, condensers, seawater applications. | ≥2 mm tube/plate |

| ERCuZn-A | Copper-Zinc | General-purpose brazing of steels, cast irons, and copper alloys. | ≥1.5 mm sheet to plate |

- Automotive & sheet repair → ERCuSi-A is the most common brazing wire for car body panels and galvanised steels, as it limits burn-through and preserves coatings.

- Dissimilar joints → ERCuAl and ERCuZn wires allow joining of steels to copper alloys where normal welding would fail.

- Marine & HVAC → ERCuNi is widely used in piping systems for its corrosion resistance in seawater and brine.

- Thin sheet advantage → Because brazing runs cooler than welding, it’s perfect for sheet work that would otherwise warp.

In MIG welding, choosing the right wire is critical. The AWS classification system gives welders a straightforward way to identify and compare wires, making it easier to match the right filler to the job. By understanding these codes, you can improve weld quality, boost efficiency, and avoid costly mistakes.

As materials and processes keep evolving, knowing how to read these classifications will stay essential. Whether you’ve been welding for years or are just getting started, this guide is designed to help you cut through the complexity and select wires with confidence.