Description

Sifmig 968 MIG Brazing Wire – 1.0 mm x 4 Kg

Sifmig 968 is a MIG brazing wire composed of copper with 3% silicon and 1% manganese. This unique composition makes it ideal for fusion welding materials of similar composition, as well as copper alloys like brass. Additionally, it’s a versatile wire suitable for MIG brazing steels, surfacing steel, and even dissimilar metal applications. The added silicon and manganese enhance the wire’s flow properties and wear resistance.

Features and Benefits:

- Composition: Contains 3% silicon and 1% manganese, providing excellent flow properties and wear resistance.

- Versatility: Suitable for fusion welding, MIG brazing steels, surfacing steel, and dissimilar metal applications.

- High-Quality Welds: Ensures consistent and strong welds, especially on materials of similar composition and copper alloys.

- Diverse Applications: Can be used in various industries and for different purposes, from shipbuilding to sculpture making.

Common Applications:

- Shipbuilding and offshore projects

- Automotive industry

- Heating and ventilation systems

- Sculpture making and repair

- Manufacturing of bronze statues, castings, and tubular products

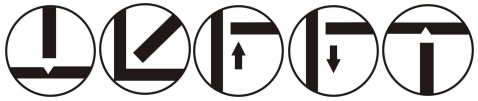

Welding Positions

Typical Weld Metal Composition

| Mn (Manganese) | 1% |

| Si (Silicon) | 3% |

| Cu (Copper) | Balance |

Typical Mechanical Properties

| Melting Point | 980-1020°C |

| Ultimate Tensile Strength | 350 N/mm² |

| Hardness | 90 |

Specifications

| Product Type | Mig Wire – Brazing |

| Part Number | WO961040 |

| Weight | 4 KG |

| Diameter | 1.0 mm |

| Melting Point (DegC) | 980-1020 |

| Ultimate Tensile Strength (U.T.S.) N/mm2 | 350 |

| Current Type | Direct Current (DC+) |

| Amperage Range | 35-180 Amps |

| Gas | Pure Argon |

BS: 2901 C9. EN ISO 24373: Cu 6560

Reviews

There are no reviews yet