Description

Sifmig 968 MIG Brazing Wire – 1.0 mm x 12.5 Kg

The Sifmig 968 MIG Brazing Wire, with a diameter of 1.0mm and weighing 12.5 Kg, is a copper wire enriched with 3% silicon and 1% manganese. This composition makes it apt for fusion welding materials of a similar nature, copper alloys (like brass), and for MIG brazing of steels. Additionally, it’s suitable for surfacing steel and for applications involving dissimilar metals. The presence of silicon and manganese ensures good flow during the welding process and imparts wear-resistance to the wire.

Key Features:

- Composition: Contains 3% silicon and 1% manganese.

- Versatility: Designed for fusion welding, MIG brazing steels, surfacing steel, and dissimilar metal applications.

- Flow Properties: The wire ensures a smooth welding and brazing process.

- Wear-Resistance: The wire’s composition ensures durability and longevity of the welded or brazed parts.

Typical Applications:

The Sifmig 968 MIG Brazing Wire is apt for:

- Industries such as shipbuilding and offshore, automotive, and heating and ventilation.

- Sculpture creation and repair.

- Production of bronze statues, castings, and tubular products.

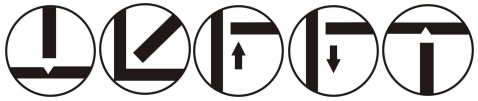

Welding Positions

Typical Weld Metal Composition

| Mn (Manganese) | 1% |

| Si (Silicon) | 3% |

| Cu (Copper) | Balance |

Typical Mechanical Properties

| Melting Point | 980-1020°C |

| Ultimate Tensile Strength | 350 N/mm² |

| Hardness | 90 |

Specifications

| Product Type | Mig Wire – Brazing |

| Part Number | WO961012 |

| Weight | 12.5 KG |

| Diameter | 1.0 mm |

| Melting Point (DegC) | 980-1020 |

| Ultimate Tensile Strength (U.T.S.) N/mm2 | 350 |

| Current Type | Direct Current (DC+) |

| Amperage Range | 35-180 Amps |

| Gas | Pure Argon |

BS: 2901 C9. EN ISO 24373: Cu 6560

Reviews

There are no reviews yet