Description

Sifmig No 8 Phosphor Bronze MIG Brazing Wire – 1.2 mm x 12.5 Kg

The Sifmig No 8 Phosphor Bronze MIG Brazing Wire, with a diameter of 1.2mm and weighing 12.5 Kg, is a high-quality phosphor bronze wire that contains 7% tin. This wire is specifically crafted for fusion welding of phosphor bronze castings, copper alloys, and brass. Additionally, it is versatile enough to be employed for MIG brazing on ferrous, stainless, and dissimilar metals, making it an excellent choice for applying a bearing surface.

It’s a preferred choice for welding bronze, brass, copper, and copper alloys, especially in scenarios that require crack repair in castings or the addition of a wear-resistant layer on surfaces vulnerable to abrasion. When working with metals that contain trace amounts of lead, such as LG2, it’s recommended to apply the SIFMIG 8 in stages, grinding between passes to eliminate lead from the joint and reduce porosity.

Key Features:

- Phosphor Bronze Composition: Contains 7% tin, making it suitable for fusion welding of specific metals.

- Versatility: Can be used for MIG brazing on a variety of metals, including ferrous, stainless, and dissimilar metals.

- Wear-Resistance: Ideal for adding a wear-resistant layer on surfaces that are subject to abrasion.

- Special Considerations: Designed to be applied in stages when working with metals containing trace lead to ensure optimal results.

- Welding Positions: Can be welded in all positions and is especially useful in hard-to-reach areas.

Typical Applications:

The Sifmig No 8 Phosphor Bronze MIG Brazing Wire is commonly used in:

- Metal Repair: Especially useful for crack repair in bronze, brass, and copper castings.

- Surface Enhancement: Applying a wear-resistant layer on surfaces prone to abrasion.

- General Welding: Fusion welding of phosphor bronze castings, copper alloys, and brass.

- Bearing Surfaces: Used for MIG brazing to apply a bearing surface on various metals.

- Specialized Welding: For metals containing trace amounts of lead, ensuring optimal weld quality and minimal porosity.

Specification

| Sub Category | Mig Wire – Brazing |

| Part Number | WO081212 |

| Weight | 12.5 KG |

| Diameter | 1.2 mm |

| Melting Point DegC | 900-1050 |

| U.T.S. N/mm2 | 260 |

| Current | DC = + |

| Shielding Gas | Pure Argon, or 95/5 (5%CO2) ArCO2 |

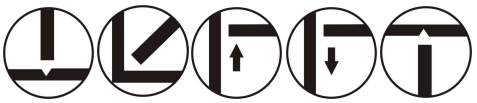

Welding Positions

Weldable in all positions and particularly useful in hard-to-reach areas. Ensure surfaces of parent metal are cleaned thoroughly before welding.

Typical Weld Metal Composition

| Sn | 7% |

| Cu | Bal |

Typical Mechanical Properties

| Melting Point | 900-1050°C |

| Ultimate Tensile Strength | 260 N/mm² |

| Hardness | 80 |

BS: 2901 C11. EN ISO 24373: Cu5180A [CuSn6P]

Reviews

There are no reviews yet