Description

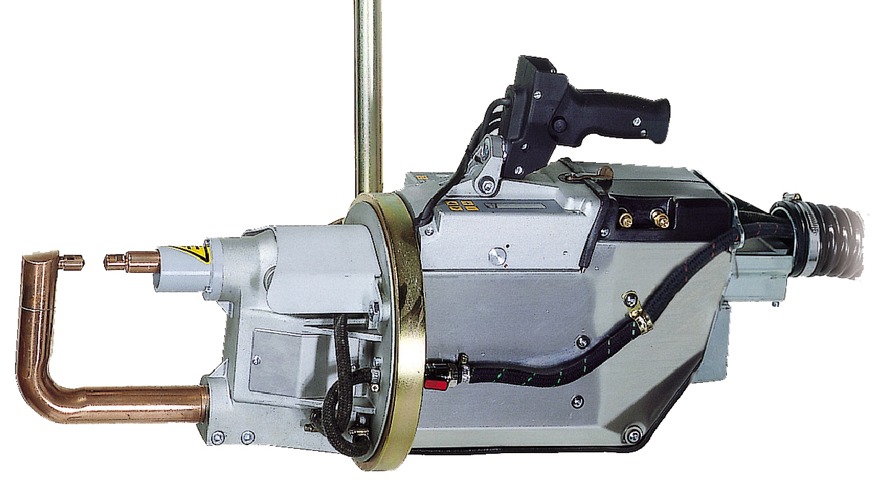

Industrial Suspended Spot Gun 23kVA “C” Type c/w TE470

Standard Unit Includes:

- Suspended spot gun with built-in control unit (TE470)

- Earth leakage and circuit breaker switch

- Air filter-regulator unit with gauge

- Supply cables and hoses 6.5m length

- Voltage and frequency to be always specified

Features:

- Pneumatic operated suspended gun, with integrated TE330, TE450, TE470 or TE480 microprocessor welding control unit

- High productivity achieved with rational design, reduced dimensions, high welding capacity

- High electric efficiency

- Reduced installation costs

- Totally enclosed, rubber protected for easy and safe operation

- Gyro suspension on sealed bearings together with a spring balancer guarantees accurate manoeuvrability at any degree

- Rotation locking device

- Large selection of arms, enabling the welder to work in a wide range of applications

- Chrome-copper electrode holders for heavy duty and long life, designed for both straight and angled assembling

- Adjustable electrodes distance, adjustable short working stroke for heavy duty

- Temporary extra stroke to reach the areas to be welded

- Long working stroke to weld reinforcement ribs, jobs in areas difficult to be reached

- Water cooled transformer with epoxy resin coated windings

- Water cooled arms, electrode holders and electrodes

- Synchronous SCR contactor insulated from cooling water circuit with protection thermostat

- Oil-free chromium-plated cylinder and shaft for heavy-duty operation and long life

The TE470 is a microprocessor welding control unit designed specifically for suspended resistance welding guns. Its primary function is to control various components of the welder, with a particular focus on regulating the thyristors that adjust the welding current. This control unit offers specialized features for working with suspended welding guns, including double stroke control and the ability to monitor the effectiveness of safety devices installed on the machine’s handle.

It’s important to note that the handle is not included as a standard component of the welding control unit. However, the machine allows for the installation of different handles, allowing users to customize the settings based on specific performance requirements.

With a generous storage capacity, the TE470 can store up to 63 different welding programs. Users can directly recall two programs using an external selector typically installed on the handle, even when multiple handles are active. Each program consists of 19 adjustable parameters that describe the working cycle in detail.

In addition to the standard 4-times cycle, the control unit enables the execution of more advanced welding processes. This includes the ability to incorporate pre-weld current, post-weld current, slope, and pulses. The TE470 is capable of operating in constant current mode, providing a display of the welding current and monitoring it against the set limit for enhanced control and accuracy.

Reviews

There are no reviews yet