Description

Hardfacing MIG Wire 1.2 mm Sifcored 600 – 5 Kg

Sifcored 600 is a gas-shielded, tubular cored hardfacing MIG wire designed for high wear resistance. It is specifically formulated for applications that demand a combination of impact and abrasion resistance. This wire is also ideal for building-up or overlay tasks, ensuring that surfaces are fortified against wear and tear.

Key Features:

- Wear Resistance: Offers high wear resistance, making it ideal for surfaces prone to abrasion and metal-to-metal wear.

- Impact Resistance: Provides a robust shield against impact, ensuring durability in challenging conditions.

- Metal Cored: Designed for surfacing parts of steel, cast steel, and high Mn steel that are exposed to abrasion, metal-to-metal wear, impact, and compression stresses.

Common Applications:

- Widely used in the earthmoving and quarry industries.

- Suitable for hardfacing digger buckets, crusher hammers, blades, etc.

- Employed in the agricultural sector for reinforcing ploughshares and similar equipment.

Materials to be Welded:

- Primarily used on mild and medium tensile steels.

- Before hardfacing, areas should be thoroughly cleaned, ensuring they are free from oil, grease, and dirt.

- Any base metal that shows signs of cracking or has previous hardfacing should be adequately removed to ensure optimal welding results.

Specifications

| Product Type |

Mig Wire – Hardfacing |

| Part Number |

WO601250 |

| Weight |

5 KG |

| Diameter |

1.2 mm |

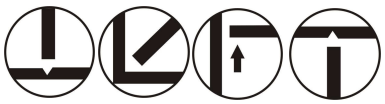

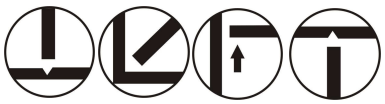

Welding Positions

Typical Mechanical Properties

| Melting Point |

1450°C |

| Ultimate Tensile Strength |

n/a N/mm² |

| Hardness |

570-650 |

Typical Weld Metal Composition

| C |

0.5% |

| Si |

1% |

| Mn |

1.5% |

| Cr |

5% |

Standards

A carriage charge is applied to orders, for standard 1-2 day shipments to mainland destinations within the United Kingdom. Other destinations and premium services are available but subject to additional freight charges.

Reviews

There are no reviews yet