Description

Double Inflatable Pipe Weld Purging System x 4″

Twin Bag Purge Systems

Sizing and specification

| Part Nº | TP04 |

| Nominal | 100 mm |

| Pipe Size | 4″ |

| Weight | 0.34 kg |

| Internal Diameter Range | 80 – 110 mm |

Description

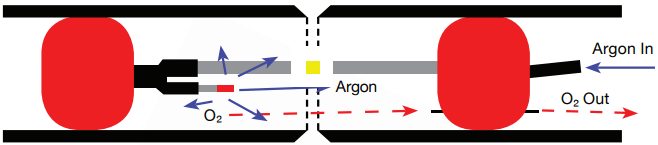

The Pipe Purge Bag Systems are widely employed in approximately 90% of traditional pipe weld purging applications to achieve bright, shiny, and oxide-free weld roots. These systems are known for their ease of use, ensuring a rapid weld purge process. The manufacturing process of these systems utilizes high-quality materials, guaranteeing the achievement of perfect oxide-free weld roots in minimal time.

The design of these systems is such that they minimize the volume of gas required for purging, resulting in significant time and inert gas savings. In fact, the return on investment can be realized after completing just one or two welds. Additionally, these robust systems are reusable, making them cost-effective in a short period.

By using a GBC Oxygen Monitor to constantly measure the oxygen content in the weld chamber the welder will know when to reduce the gas flow and commence welding.

Post-welding, the system remains in position until the weld joint temperature drops below oxidation levels. Subsequently, the purge gas feed is disconnected, and the bags deflate, allowing for the system’s withdrawal. This step ensures the maintenance of the weld’s integrity and quality.

Features and advantages

- Inflatable Pipe Purging Systems significantly reduce purging times, leading to considerable savings in labor costs.

- Purge times for different pipe sizes: 4″ pipe = 1 1/2 mins; 8″ pipe = 4 mins; 12″ pipe = 8 mins.

- Ready to use and connects to a dedicated and regulated gas supply.

- Flow rate adjustable up to 20l a min using the pre-set purge valve.

- Gas pressure control ensures an even positive root bead with no notching.

- Quick and easy installation simplifies the inert gas purging process.

- Heat resistant up to 70ºC continuously.

- Uses less inert gas (less than 2% of that required for conventional purging).

How it Works

The Gas Release Valve is pre-set and sealed, no adjustment required.

Luminous strip aids the operator to centre system to the weld gap.

Part Numbers & Sizing

| Part No. | Nominal Pipe Size (mm / inch) | Internal Diameter Range (mm) | Weight (kg) |

|---|---|---|---|

| TP01 | 25mm (1″) | 13 – 38mm | 0.20kg |

| TP1.5 | 40mm (1.5″) | 32 – 45mm | 0.20kg |

| TP02 | 50mm (2″) | 44 – 57mm | 0.34kg |

| TP03 | 75mm (3″) | 58 – 84mm | 0.34kg |

| TP04 | 100mm (4″) | 80 – 110mm | 0.34kg |

| TP05 | 125mm (5″) | 103 – 135mm | 0.38kg |

| TP06 | 150mm (6″) | 124 – 162mm | 0.38kg |

| TP08 | 200mm (8″) | 175 – 213mm | 0.90kg |

| TP10 | 250mm (10″) | 230 – 265mm | 1.0kg |

| TP12 | 300mm (12″) | 265 – 305mm | 1.1kg |

| TP14 | 350mm (14″) | 330 – 355mm | 1.3kg |

| TP16 | 400mm (16″) | 380 – 405mm | 1.7kg |

| TP20 | 500mm (20″) | 485 – 510mm | 1.9kg |

| TP24 | 600mm (24″) | 585 – 610mm | 2.5kg |

| AFH30 | 30 meter argon feed hose assembly for GBC TWIN BAG PURGE SYSTEM. |

Reviews

There are no reviews yet