Description

Devcon 14251 – 5 Minute Epoxy Devtube – 1 x 25ml

- Stock No: 14251

- Package Size: 25ml Dev-tube

Features

- Bonds rigid durable substrates such as metals, glass, ceramics, concrete and wood in all combinations

- Forms a clear hard rigid bond self levelling liquid in minutes

- Listed under NSN Stock#8040-00-264-6816:#8040-01-067-6126

- Functional strength in 1 hour

- 100% reactive, no solvents

- Low viscosity (10,000 cps)

- Open Time: 4-7 minutes

- Fixture Time: 10-15 minutes

- Colour: Clear

- Mix Ratio: 1:1

- Working Time Min: 3

- Working Time Max: 6

- Fixture Time Min: 10

- Fixture Time Max: 15

Intended Use

- Cures fast for quick metal to metal bonding and repairs

- Pots and encapsulates electronic components and assemblies

- Suitable for bonding metals, fabrics, ceramics, glass, wood and concrete (in combinations)

Physical Properties (Uncured)

| Colour | Light Amber |

| Mixed Viscosity | 10,000 cps |

| Mixed Ratio by Volume & Weight | 1:1 |

| Working Time (28 grams @ 23°C) | 3 – 6 minutes |

| Fixture Time | 10 – 15 minutes |

| Functional Cure @ 23°C | 45 – 60 minutes |

| Full Cure | 12 hours |

| Mixed Density | 1.10 gm/cc |

Performance characteristics (7 days cured at 24°C)

| Adhesive tensile shear, ASTM D1002 | 13 MPa |

| T Peel | 4-5 N/10mm |

| Service temperature, dry | 0 – 93°C |

| Tensile Elongation | 1% |

| Specific Volume | 909 cm³/kg |

| % solids by volume | 100 |

| Cured hardness, ASTM D2240 | 85D |

| Dielectric strength, ASTM D149 | 19.6 KV/mm |

Chemical Resistance – 7 days room temperature cure (30 days immersion)

| Acetic (dilute) 10% | Poor |

| Acetone | Poor |

| Ammonia | Poor |

| Corn Oil | Excellent |

| Cutting Oil | Excellent |

| Ethanol | Poor |

| Petrol (unleaded) | Excellent |

| Glycols/Antifreeze | Fair |

| Hydrochloric 10% | Poor |

| Isopropanol | Poor |

| Kerosene | Excellent |

| MEK | Poor |

| Mineral Spirits | Excellent |

| Motor Oil | Excellent |

| Sodium Hydroxide 10% | Poor |

| Sulphuric 10% | Poor |

Surface Preparation

5 Minute Epoxy works best on clean surfaces. Surfaces should be free of heavy deposits of grease, oil, dirt or other contaminants, or cleaned with industrial cleaning equipment such as vapour phase degreasers or hot aqueous baths. Abrading or roughing the surfaces of metals will increase the microscopic bond area significantly and optimise the bond strength.

Mixing

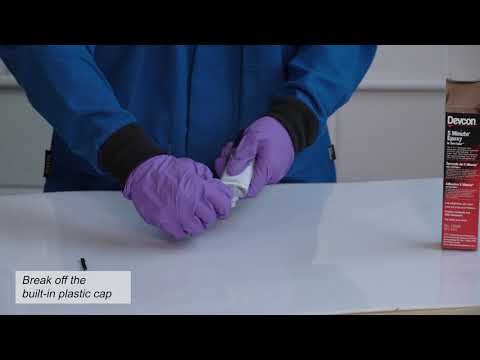

This product is available in cartridge, non-cartridge and 28g Devtube form.

Cartridge Form:

The cartridge should be used with the appropriate manual Applicator Gun and Static Mixer Nozzle. The Static Mixer Nozzle enables the epoxy to be dispensed, metered and directly applied to the surfaces to be bonded.

Please note: Once the product cures in the nozzle it has to be thrown away and a new nozzle used.

Non-Cartridge Form:

Proper homogenous mixing of the two epoxy components of resin and hardener are essential for the curing and development of stated strengths. Always mix the two components with clean tools, preferably of a disposable design.

For small amounts use Devcon’s 28g Devtube, which comes with it’s own plunger to extrude the two components at an equal rate.

Application Apply mixed epoxy directly to one surface in an even film or as a bead. Assemble with the mating part within the recommended working time. Obtain firm contact between the parts to minimize any gap and ensure good contact of the epoxy with the mating part. A small amount of epoxy should flow out the edges to show there is adequate gap filling. For very large gaps, apply epoxy to both surfaces and spread to cover the entire area, or make a bead pattern, which will allow flow throughout the joint.

Let bonded assemblies stand for the recommended functional cure time before handling. They are capable of withstanding processing forces at this point, but should not be dropped, shock loaded or heavily loaded.

Storage

Shelf Life

Devcon Epoxy Adhesives should be stored in a cool, dry place when not used for a long period of time. A shelf life of 3 years from date of manufacture can be expected when stored at room temperature 22ºC in their original containers.

Precaution For complete safety and handling information please refer to the appropriate Materials Safety Data Sheets prior to using this product.

Warranty

Devcon will replace any material found to be defective. Because the storage, handling and application of this material is beyond our control we can accept no liability for the results obtained.

Disclaimer

All information on this data sheet is based on laboratory testing and is not intended for design purposes. ITW Devcon makes no representations or warranties of any kind concerning this data.

Reviews

There are no reviews yet