Description

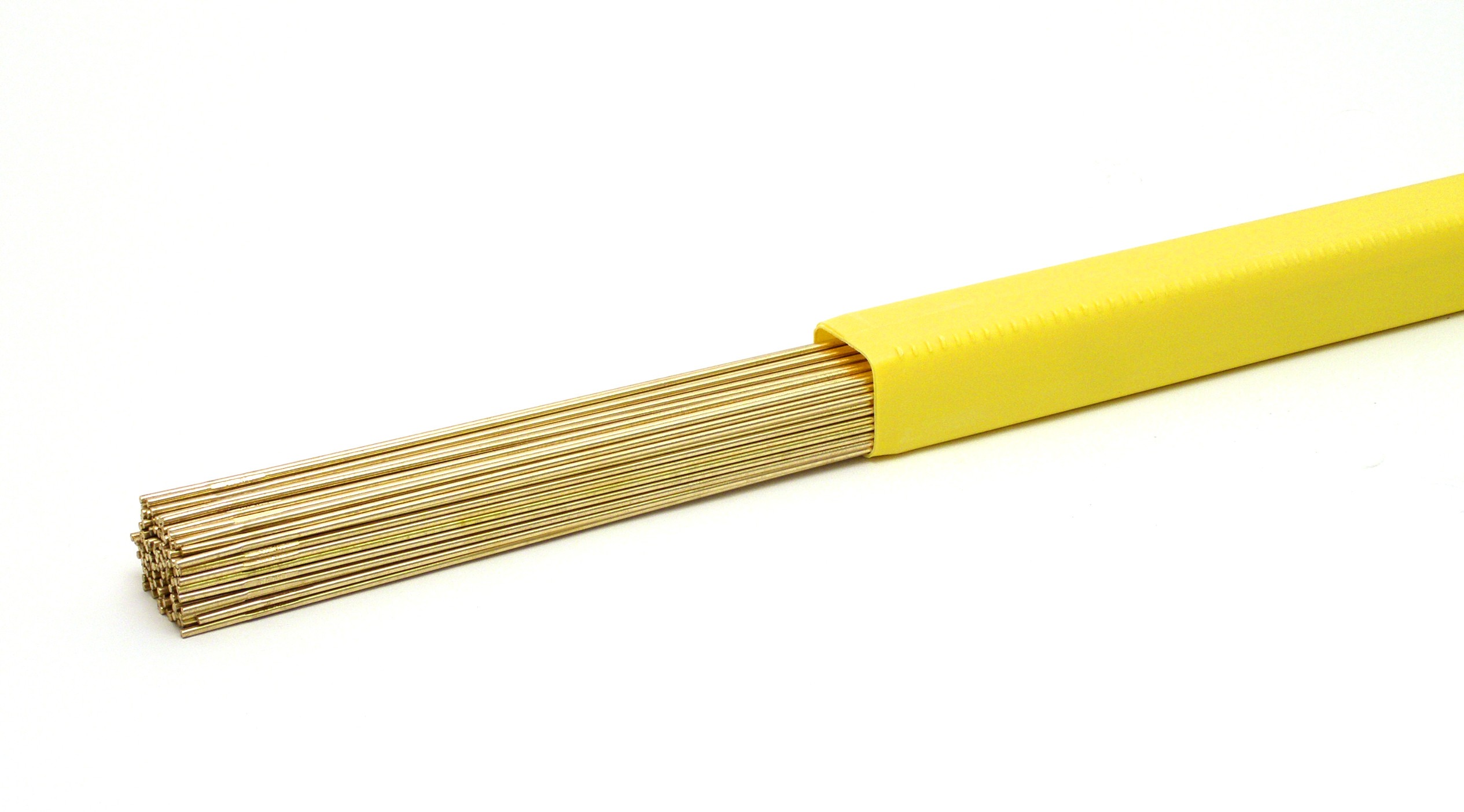

SIFALBRONZE No 32 – Aluminium Bronze TIG Rods – 2.4 mm x 2.5 Kg

SIFALBRONZE No 32 is a 90/10 aluminium bronze TIG rod, designed specifically for welding materials of a similar composition. This versatile rod is not only used for surfacing and creating dissimilar metal joints but also for TIG brazing on ferrous and dissimilar metals. It’s a preferred choice in industries like ship-building, offshore power generation, and for repair and maintenance processes. The alloy is known for its exceptional wear and corrosion resistance, making it ideal for building up or overlapping surfaces.

Features and Benefits:

- Versatile Welding: Suitable for surfacing, creating dissimilar metal joints, and TIG brazing.

- Dissimilar Metal Joining: Can be used for TIG brazing on ferrous and dissimilar metals.

- Industry Applications: Widely used in ship-building, offshore power generation, and repair and maintenance processes.

- Enhanced Resistance: Offers excellent wear and corrosion resistance.

Common Applications:

- Aluminium Bronze Alloys: Ideal for welding CuAl 8Fe3, CuAl 10FeMn2, CuAl 9Mn9, and cast aluminium bronzes G-CuAl8 and G-CuAl10Ni.

- Dissimilar Metals: Can be used to braze aluminium bronze to steel and copper to steel.

Welding Positions

Material To Be Welded

Can be used on aluminium bronze alloys: CuAl 8Fe3, CuAl 10FeMn2, CuAl 9Mn9, and cast aluminium bronzes G-CuAl8 and G-CuAl10Ni.

Can be used to braze some dissimilar metals, including aluminium bronze to steel, and copper to steel.

Technical Data

- Current Amps: 40 – 180

- Current: DC = +

- Shielding Gas = Pure Argon

Typical Weld Metal Composition

| Al | 10 % |

| Fe | 1 % |

| Cu | Bal |

Typical Mechanical Properties

| Melting Point | 1030°C |

| Ult Tensile Strength | 500 N/mm² |

| Hardness | 95 |

Standards

| EN 14640 | Cu 6180 (CuAl10), |

| BS: 2901 | C.13 |

| AWS A5.7 | ERCu AL-A2 |

Reviews

There are no reviews yet