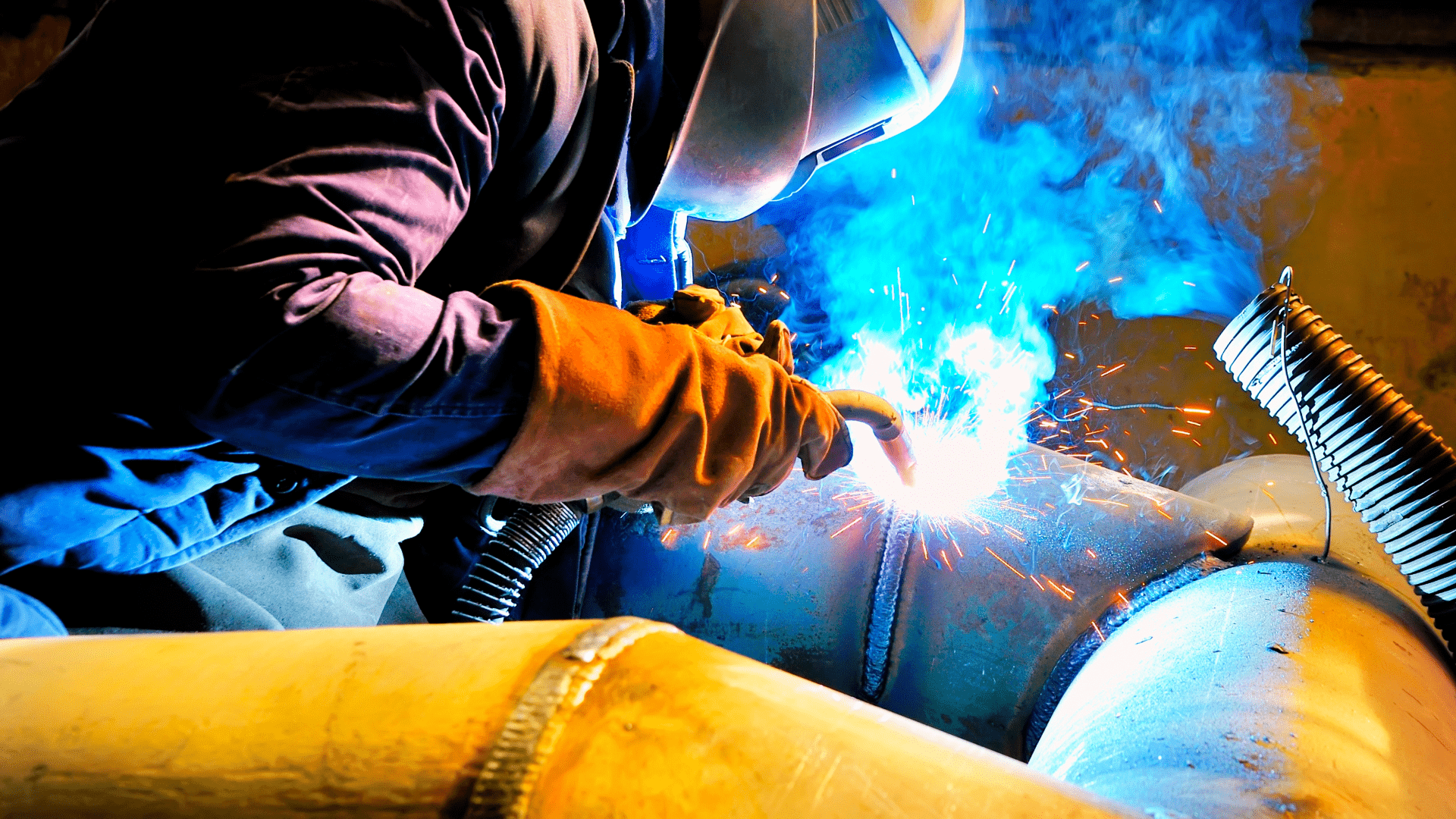

MIG (Metal Inert Gas) welding is a popular welding process that involves feeding a spool of wire through a MIG torch and into the weld pool. It is a versatile process that can be used for a wide range of welding applications, from DIY to heavy-duty industrial production work. MIG welding equipment is available in various types, each designed for specific applications. Choosing the right MIG welding equipment is crucial to achieve high-quality welds and increase productivity. In this article, we will discuss the different types of MIG welding equipment available and their applications, to help you choose the right equipment for your welding needs.

In this guide:

Huge Savings on MIG Welders

Discover a diverse range of MIG welders tailored to meet the demands of both professional and hobbyist welders.

Single Phase Entry Level (DIY) Type

Single-phase entry-level MIG welding equipment is designed for do-it-yourself (DIY) users and light-duty repair applications. It is highly portable and features a complete MIG welding package, including a MIG torch, work return clamp, and selected accessories. The equipment also has step-less current control and a turbo fan-cooled MIG welding unit with a non-live MIG torch and work return clamp.

This type of MIG welding equipment is suitable for welding 0.6mm to 0.8mm mild steel wire on up to 5kg reels. Its portability makes it ideal for DIY and car body repairs, as it is easy to transport and operate.

The main advantage of single-phase entry-level MIG welding equipment is its affordability, making it an excellent choice for beginners or those on a budget. It is also easy to use, and its compact size makes it ideal for smaller welding projects.

However, there are some limitations to single-phase entry-level MIG welding equipment. Due to its low amperage output, it may not be suitable for welding thicker metals. It may also struggle to weld for extended periods, as it lacks the power and duty cycle of larger MIG welding machines.

Overall, single-phase entry-level MIG welding equipment is an excellent choice for DIY users and those looking to start welding as a hobby. Its affordability, portability, and ease of use make it a popular choice for beginners, although it is limited in its capabilities compared to larger and more powerful MIG welding machines.

Single Phase Up To 300amps

Single-phase MIG welding equipment packages with outputs up to 300 amps are ideal for welding in small workshops, auto body shops, and light fabrication applications. These machines are designed to be portable and compact, making them easy to transport from one job site to another.

The features of single-phase MIG welding equipment packages up to 300 amps include a Euro connection torch, step-less current control, and a heavy-duty under gear that can hold a full-size gas cylinder. These machines are capable of welding wire sizes ranging from 0.6mm to 1.2mm on reels of up to 15kg. They can also be used to weld aluminium, although the quality may not be as good as that achieved with Pulsed MIG welding. These machines typically require a fuse rating of up to 32 amps to operate.

The advantages of using single-phase MIG welding equipment packages up to 300 amps include their portability, compact size, and ease of use. They are also relatively affordable compared to larger welding equipment packages, making them a great choice for small businesses or hobbyists. Additionally, these machines are capable of producing high-quality welds on thin and medium-thickness materials.

However, there are also some disadvantages to using single-phase MIG welding equipment packages up to 300 amps. They are not suitable for heavy-duty industrial applications due to their lower amperage output. The quality of welds on aluminium may also not be as good as with other types of MIG welding machines. Furthermore, these machines may not have as many features and options as larger, more advanced welding machines.

Overall, single-phase MIG welding equipment packages up to 300 amps are a great choice for light-duty welding applications where portability and ease of use are important factors. They are capable of producing high-quality welds on a range of materials and are an affordable option for small businesses and hobbyists.

3 Phase With Pulse Arc Control

3-phase MIG welding equipment packages with pulse arc control are designed to offer an infinitely variable power inverter welding machine for MIG/MAG welding of steels, stainless steels, and aluminium. This equipment is also suitable for welding using bronze wires, as recommended for the repair of car bodywork.

The pulse arc control feature allows for greater control over the welding process, resulting in a more precise and consistent weld. These machines are capable of producing high-quality welds on thin materials, such as aluminium, comparable to the quality obtained on much thinner sections using GTAW.

The equipment packages are normally supplied complete with a 4-roll drive wire feed unit, a water cooler/recirculation unit, and a MIG torch. The 4-roll drive wire feed unit ensures a steady and consistent wire feed, while the water cooler/recirculation unit prevents overheating of the equipment during prolonged use.

3-phase MIG welding equipment packages with pulse arc control have multiple advantages, including:

- Infinitely variable power control, providing greater control over the welding process

- Capable of producing high-quality welds on thin materials, such as aluminium

- Versatile and suitable for welding using bronze wires

- Complete with a 4-roll drive wire feed unit and water cooler/recirculation unit for consistent and steady operation.

However, there are also some disadvantages to using 3-phase MIG welding equipment packages with pulse arc control, including their higher cost compared to other types of MIG welding equipment. Additionally, these machines require a 3-phase power supply, which may not be available in all work environments.

3-phase MIG welding equipment packages with pulse arc control are ideal for industrial and heavy-duty production work, where precise and consistent welding is required on a variety of materials.

3 Phase Multi-Systems

3-phase multi-process MIG welding machines are versatile welding equipment that can perform multiple welding processes. They are available in various specifications, from conventional CC/CV systems to the more popular inverter technology MIG welding packages.

These machines have outstanding arc characteristics on both constant current and constant voltage processes. This provides great welding versatility with Stick, MIG, and cored wires, with the option of a TIG facility in a single power source. They are ideal for welding in industries such as construction, fabrication, and shipbuilding.

The advantage of 3-phase multi-process MIG welding machines is that they provide great flexibility and versatility in terms of welding processes, as they can perform different welding processes such as MIG, Stick, and TIG welding. They also have excellent arc characteristics, which produce quality welds.

The disadvantages of using 3-phase multi-process MIG welding machines are that they are more expensive than single-phase MIG welding machines. They also require a 3-phase power supply, which may not be available in some locations.

Despite these disadvantages, 3-phase multi-process MIG welding machines offer greater flexibility, versatility, and better welding quality, making them an ideal choice for professional welders who require the ability to perform different welding processes using a single machine.

Summary

| Type of MIG Welding Equipment | Pros | Cons | Suitable Uses |

|---|---|---|---|

| Single Phase Entry Level (DIY) Type | Highly portable, complete package | Limited power, suitable for light-duty work only | DIY and light repair applications |

| Single Phase Up to 300 amps | Euro connection torch, high amperage output | Not suitable for high-quality welding of aluminum, may require high fuse rating | Welding of steel and aluminum up to 1.2mm diameter |

| 3 Phase Up to 500 amps | High-duty cycle, multiple output voltage positions | Requires 3-phase power, expensive | Welding of steel, stainless steel, aluminum, and bronze wires up to 1.2mm diameter |

| 3 Phase with Pulse Arc Control | Infinitely variable power, high-quality welding of aluminum | Expensive, may require additional equipment | MIG/MAG welding of steel, stainless steel, and aluminum |

| 3 Phase Multi-Systems | Versatile, can be used for multiple processes including TIG | Expensive, may require additional equipment | Stick, MIG, and cored wire welding, with TIG option |

In conclusion, there are various types of MIG welding equipment available for different applications, ranging from single-phase entry-level DIY types to multi-process MIG welding machines. The type of equipment needed for a job will depend on the specific requirements, such as the welding material, thickness, and welding process. Choosing the right MIG welding equipment is crucial to achieving high-quality welds with efficiency and ease. Therefore, it is important to assess the welding needs and select the most suitable equipment for the job. With the right MIG welding equipment, a welder can achieve excellent welds, whether in DIY or industrial applications.